In the realm of product development, the importance of prototyping cannot be overstated. It serves as the bridge between concept and reality, enabling engineers and designers to test ideas, refine concepts, and bring innovation to life. Among the pivotal components of this process is the Rapid Prototype Enclosure (RPE). In this post, the author would give a brief introduction to the rapid prototype enclosure.

What is a Rapid Prototype Enclosure?

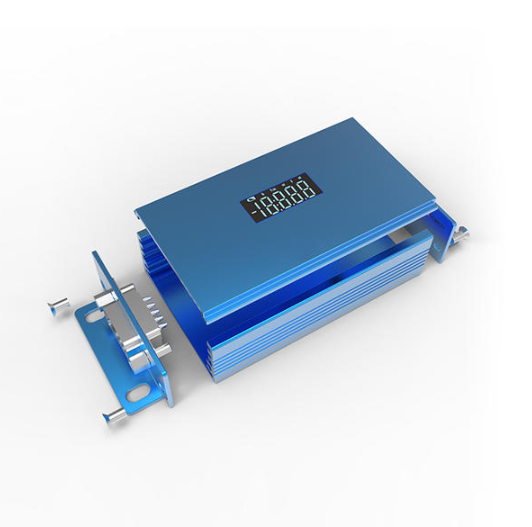

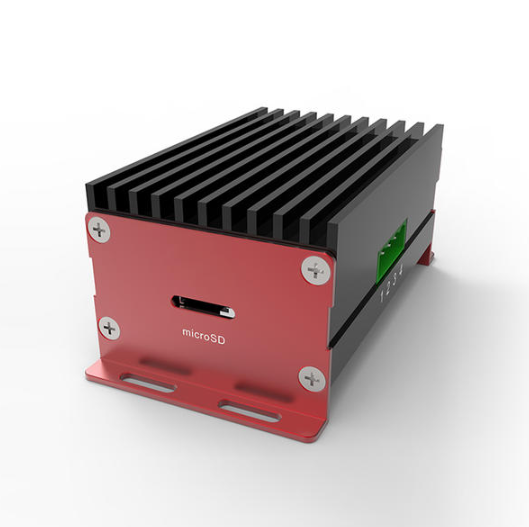

A rapid prototype enclosure (RPE) is a housing or casing that encapsulates and protects a prototype device or product during the developmental phase. It provides a physical structure that mimics the final product's form factor and dimensions. RPEs are typically created using various rapid prototyping techniques such as 3D printing, CNC machining, or injection molding. Their primary function is to encase and safeguard the internal components of a prototype, offering a tangible representation of the envisioned end product.

What is the Use of a Rapid Prototype Enclosure?

The primary purpose of a rapid prototype enclosure is to offer a tangible representation of the final product's aesthetics, size, and functionality. It provides a protective shell that houses the internal components of a prototype device or product.

Beyond mere protection, RPEs serve as a platform for testing and validation. Engineers and designers use these enclosures to evaluate the ergonomics, user experience, and functionality of the prototype before moving to the production phase. RPEs allow for modifications and iterations, facilitating a more efficient and accurate development process.

Beyond mere protection, RPEs serve as a platform for testing and validation. Engineers and designers use these enclosures to evaluate the ergonomics, user experience, and functionality of the prototype before moving to the production phase. RPEs allow for modifications and iterations, facilitating a more efficient and accurate development process.

What are the Advantages of Rapid Prototype Enclosure?

Rapid prototype enclosures are not just protective casings; they are catalysts for innovation, enabling a seamless fusion of creativity, functionality, and practicality in product development.

Their advantages extend far beyond the physical representation, influencing the entire product lifecycle and contributing significantly to its success in the market. Here are the main advantages of the rapid prototype enclosure:

Their advantages extend far beyond the physical representation, influencing the entire product lifecycle and contributing significantly to its success in the market. Here are the main advantages of the rapid prototype enclosure:

Streamlined Iterative Development

RPEs act as the cornerstone for iterative design, fostering a dynamic development environment where changes can be swiftly implemented and tested. This fluidity not only accelerates the design cycle but also allows for a more responsive approach to incorporating feedback. Teams can adapt to evolving requirements or innovative ideas, refining the product in a timely manner.

Enhanced Visual Representation

Beyond merely offering a physical form, RPEs serve as a visual aid that helps stakeholders grasp the essence of the product. This tangible representation facilitates clearer communication among team members, investors, and potential customers. Seeing and feeling a prototype in its enclosure often sparks valuable insights and discussions, refining the vision collectively.

Rigorous Testing and Validation

The real-world simulation provided by RPEs is invaluable. Engineers can subject the prototype to various tests, assessing its performance, durability, and usability. Identifying flaws early in the process not only saves time but also ensures that the final product meets or exceeds user expectations, enhancing its market readiness and reliability.

Cost-Efficient Design Refinement

The cost savings achieved by using RPEs cannot be overstated. By catching and rectifying design flaws early in the prototyping stage, companies avoid the astronomically higher costs associated with modifying a fully developed product or tooling during mass production. This foresight significantly reduces expenses and mitigates risks associated with market failure due to overlooked design issues.

Unparalleled Customization and Adaptability

Rapid prototyping techniques empower designers to explore various design iterations and configurations swiftly. This flexibility facilitates adaptations to changing requirements or feedback without major production interruptions. RPEs accommodate design alterations efficiently, allowing for quick adjustments and refinements throughout the developmental journey.

Holistic Integration with Design Process

RPEs don't exist in isolation; they are an integral part of the overall design process. Their presence fosters a collaborative environment where cross-disciplinary teams collaborate closely, iterating on ideas in real-time. This holistic integration results in a more cohesive and refined final product, aligning the efforts of all stakeholders toward a common goal.

Conclusion

All in all, rapid prototype enclosures play a pivotal role in the product development process by providing a tangible and functional representation of a prototype. They facilitate iterative design, testing, and validation, ultimately contributing to the creation of refined, functional, and market-ready products. Incorporating RPEs into the development cycle proves to be a strategic investment that enhances efficiency and ensures the delivery of high-quality end products.