In an era where healthcare is rapidly evolving, Remote Patient Monitoring (RPM) has emerged as a game-changing solution, revolutionizing the way we approach patient care. At the heart of this transformation lies a critical component often overlooked: the RPM enclosure.

These specialized aluminum enclosures are not just protective shells; they're the important for enabling the seamless integration of technology and healthcare. Let's dive into how RPM enclosures are reshaping the landscape of remote patient care.

The Rise of Remote Patient Monitoring

Remote Patient Monitoring has seen an unprecedented surge in adoption, particularly in the wake of global health challenges. According to recent studies, the RPM market is expected to grow at a staggering annual rate of 12.1% between 2024 and 2031. This growth is driven by the numerous benefits RPM offers:

Enhanced Patient Outcomes: Continuous monitoring leads to early detection of health issues.

Reduced Healthcare Costs: Fewer in-person visits and hospitalizations.

Improved Patient Satisfaction: Comfort of being monitored from home.

Efficient Resource Allocation: Healthcare providers can manage more patients effectively.

The Critical Role of RPM Enclosures

At the core of every effective RPM system is a robust, reliable enclosure. These custom aluminum enclosures are designed to house the sensitive electronic components that make remote monitoring possible. Here's why they're indispensable:

Protection Against Environmental Factors: RPM devices often operate in diverse settings, from sterile hospital rooms to patients' homes. The enclosures must be:

- Waterproof and dust-resistant

- Able to withstand accidental impacts

- Resistant to various temperatures and humidity levels

Electromagnetic Interference (EMI) Shielding:

In a world filled with electronic devices, RPM enclosures must protect the sensitive monitoring equipment from electromagnetic interference, ensuring accurate data transmission.

Thermal Management: Many RPM devices generate heat during operation. Aluminum enclosures excel in heat dissipation, maintaining optimal operating temperatures for the electronics inside.

Ergonomic Design: RPM devices need to be user-friendly for both healthcare providers and patients. Well-designed enclosures contribute to ease of use and patient comfort.

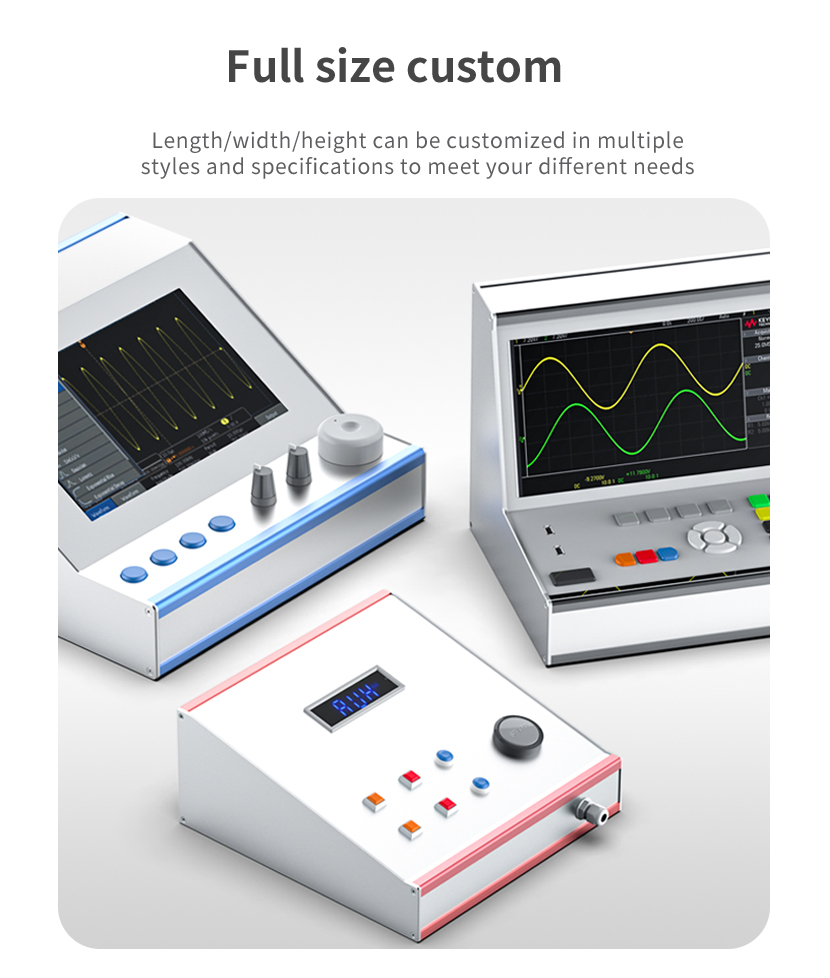

Customization Capabilities: Every healthcare application has unique requirements. Custom RPM enclosures can be tailored to specific needs, accommodating various sensors, displays, and connectivity options.

Advanced Features of Modern RPM Enclosures

Today's RPM enclosures are pushing the boundaries of what's possible in remote healthcare. Here are some cutting-edge features:

High-Resolution Imaging: Modern RPM enclosures are designed to house high-resolution cameras, enabling detailed visual assessments of patients.

Low Light and NIR Imaging: Advanced enclosures support cameras that can operate in low light conditions and even use Near-Infrared (NIR) imaging for night-time monitoring.

Pan, Tilt, and Zoom Functionality: RPM enclosures are now built to accommodate movable camera systems, allowing for comprehensive patient observation.

Integration of Multiple Sensors: From heart rate monitors to blood oxygen sensors, modern RPM enclosures can house a variety of monitoring devices in a single, compact unit.

Designing the Ideal RPM Enclosure

Creating the perfect RPM enclosure requires a delicate balance of form and function. Here are key considerations in the design process:

Material Selection: Aluminum is often the material of choice due to its lightweight nature, excellent thermal properties, and corrosion resistance.

Ingress Protection: RPM enclosures must meet specific IP ratings to ensure protection against water and dust ingress.

Ergonomics: The design should prioritize ease of use for both healthcare providers and patients, with smooth contours and intuitive interfaces.

Aesthetics: While functionality is paramount, the visual appeal of RPM devices can contribute to patient acceptance and compliance.

Regulatory Compliance: RPM enclosures must adhere to strict medical device regulations, including those related to materials, manufacturing processes, and safety standards.

The Future of RPM Enclosures

As technology continues to advance, we can expect RPM enclosures to evolve in exciting ways:

Integration of AI and Machine Learning: Future enclosures may house more powerful processors, enabling on-device AI for real-time health analysis.

Improved Connectivity: With the rollout of 5G networks, RPM enclosures will need to accommodate advanced communication modules for faster, more reliable data transmission.

Enhanced Battery Life: Innovations in power management and battery technology will lead to RPM devices that can operate longer between charges.

Sustainable Materials: As environmental concerns grow, we may see a shift towards more eco-friendly materials and manufacturing processes for RPM enclosures.

Conclusion: Empowering Healthcare Through Innovation

RPM enclosures are more than just protective casings; they're the enablers of a healthcare revolution. By providing a secure, reliable housing for advanced monitoring technology, these custom aluminum solutions are helping to bridge the gap between patients and healthcare providers, regardless of physical distance.

As we look to the future, the continued evolution of RPM enclosures will play a crucial role in expanding the possibilities of remote healthcare. From improving patient outcomes to reducing healthcare costs, these innovative solutions are set to transform the medical landscape, one enclosure at a time.

For healthcare providers and medical device manufacturers looking to stay at the forefront of this revolution, partnering with experienced aluminum enclosure manufacturers is key. By leveraging custom solutions tailored to specific RPM needs, we can collectively work towards a future where quality healthcare is accessible to all, anytime and anywhere.