Did you know that selecting the right enclosures for electronic projects can significantly extend the lifespan of your components? Whether you are working on a small DIY project or managing a large-scale industrial application, the right enclosure not only protects your components but also ensures optimal performance. This article will delve into the best enclosures for electronic projects, focusing on aluminum enclosures, their benefits, and why they are the preferred choice for many professionals.

Why Choose Aluminum Enclosures?

Aluminum enclosures for electronic projects offer a range of benefits that make them ideal:

Lightweight and Strong: Aluminum has a high strength-to-weight ratio, making it both lightweight and durable. This is crucial for portable projects or installations where weight is a concern.

Corrosion Resistance: Aluminum is highly resistant to corrosion, ensuring longevity even in harsh environments.

Heat Dissipation: Excellent thermal conductivity makes aluminum perfect for heat dissipation, protecting sensitive electronic components from overheating.

Customizability: Aluminum enclosures for electronic projects can be easily customized with various finishes and modifications, making them versatile for different applications.

Types of Aluminum Enclosures

Understanding the different types of aluminum enclosures for electronic projects can help you choose the best one for your needs:

Extruded Aluminum Enclosures

Extruded aluminum enclosures for electronic projects are formed by pushing aluminum through a die to create a specific shape. These enclosures are ideal for applications requiring consistent dimensions and excellent heat dissipation. They are commonly used in linear power supplies, amplifiers, and control units.

Cast Aluminum Enclosures

Cast aluminum enclosures for electronic projects are made by pouring molten aluminum into a mold. This method allows for complex shapes and designs, making them suitable for demanding applications and harsh environments. They offer robust protection and are often used in industrial settings.

Sheet Metal Enclosures

These enclosures for electronic projects are created by cutting and bending sheets of aluminum. They are highly customizable and suitable for various shapes and sizes. Sheet metal enclosures are often used when flexibility in design is crucial, such as in prototyping.

CNC Machined Enclosures

CNC machined enclosures for electronic projects are crafted by cutting away material from a solid block of aluminum using computer numerical control (CNC) machines. These enclosures offer high precision and can accommodate complex geometries with tight tolerances, making them ideal for applications requiring exceptional accuracy.

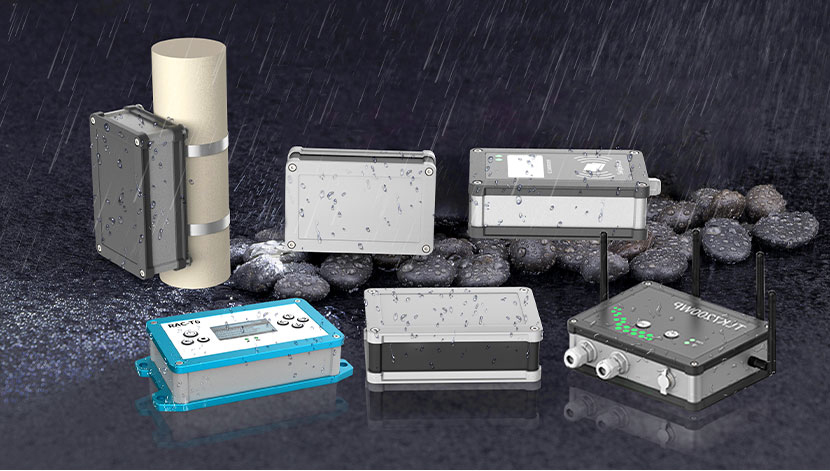

Waterproof Aluminum Enclosures

Waterproof aluminum enclosures for electronic projects provide exceptional protection against moisture and water ingress. They are designed for outdoor or damp environments, ensuring the safety and longevity of sensitive electronic components. These enclosures are perfect for projects requiring durable and secure housing solutions in challenging conditions.

Design Considerations for Aluminum Enclosures

When designing aluminum enclosures for electronic projects, several key factors must be considered to ensure optimal performance and durability:

Quality Control: Implement stringent quality control measures, including dimensional checks, pressure tests, and corrosion resistance evaluations, to ensure enclosures meet specifications.

Tolerances and Fit: Define precise tolerances for components and assemblies to ensure proper fit and alignment, preventing gaps and ensuring reliability.

ESD Protection: Incorporate electrostatic discharge (ESD) protection features if the enclosure houses sensitive electronic components. ESD coatings or grounding mechanisms can prevent static electricity from damaging components.

Water and Dust Ingress Prevention: Use seals, gaskets, and specialized coatings to prevent water and dust ingress, especially in outdoor or dusty environments.

User Safety Features: Integrate safety features like locking mechanisms, tamper-evident seals, or emergency shutdown switches based on the intended application and user needs.

Customization Options at YONGU

At YONGU, we offer a range of customization options to ensure your aluminum enclosures for electronic projects meet your specific needs:

Design: Our professional design team can create 3D files, CAD documents, and CDR vector diagrams tailored to your project requirements.

CNC Milling and Turning: With over 10 CNC machines, we can handle both large-scale production and single samples, ensuring high-quality products with efficiency.

Anodizing and Surface Treatments: Enhance the corrosion resistance, surface hardness, and wear resistance of your enclosures with our anodizing treatments. Choose from various colors for added aesthetic appeal.

Printing: Add logos or other designs to your enclosures using laser engraving or silk screen printing, meeting multiple color requirements.

Conclusion

Choosing the right enclosures for electronic projects is crucial for the protection and performance of your components. Aluminum enclosures offer unparalleled benefits, including durability, heat dissipation, and customization options. By understanding the different types of aluminum enclosures and their design considerations, you can make an informed decision that will enhance the longevity and reliability of your projects.

At YONGU, we are committed to providing high-quality, custom aluminum enclosures for electronic projects tailored to your specific needs. Contact us today to learn more about our offerings and how we can help you protect and organize your electronic projects.