Metal is naturally prone to corrosion. We all know how metal was able to change and ease the life of people nowadays. Since then metals are treated to prevent degradation. Corrosion is the deterioration of the surface of the metal due to chemical processes undergone by the metal with its environment. If the metal is located in a moist area and an oxidizing agent also known as electron acceptor corrosion occurs. One obvious presence of corrosion is rust. Once the metal is corrosive, they become unstable, easily collapse, and become unsafe for use.How Do We Prevent Corrosion In Metals? In preventing the corrosion of metals, consider these;

Type of Metal

Aluminum and stainless steel are some of the commonly used metals that have excellent anti-corrosive properties. These metals require less treatment for additional corrosion protection.

Protective Coatings

Protective coating when applied to metals is a cost-effective way of reducing the possibility of corrosion. Examples of protective coating are the application of paint coating and powder coating. Then the metal is heated to create that smooth surface. Some products of powder coating contain acrylic, polyester, urethane, nylon, and epoxy.

Environmental Factors

Naturally, corrosion occurs as a result of the chemical reaction of the metal and the present gases in the environment. To minimize chemical reactions, the environmental factors must be controlled. It is as easy as keeping the moist away from the metals. Other complex measures include reducing the amount of sulfur, chlorine and oxygen in the air to prevent oxidization.

Sacrificial Protection or Coating

Surfaces of the metal are intentionally oxidized to increase the durability of the metal, thus calling it a sacrificial coating. There are two main ways of sacrificial coating: Cathodic protection and Anodic Protection. In Cathodic protection, iron alloy steel is coated with zinc or also known as galvanizing. It is commonly used in a water heater, ship hulls, and offshore oil platforms. While in anodic protection, a less active metal such as tin is coated to the iron alloy steel. Tin does not easily corrode thus protecting the metal.

After considering all these properties in preventing corrosion to your metals, let us now move to a more high technology way of protecting your metals, especially aluminum alloys.

Benefits Of Anodized Aluminum Alloy

Throughout the years, anodized aluminum alloy acts as one of the most high-quality materials for household, commercial and industrial needs. The process of anodizing aluminum creates a thin layer integral to the aluminum alloy that acts as the protective coating while allowing the metal to be colored in any shade. The coating acts as protection from corrosion, abrasion, and weathering. Here are some of the benefits of anodized aluminum alloy;

Protection from harsh weather conditions.

Enhanced corrosion protection

Abrasion-resistant

Lighter and harder aluminum shell

Nonconductive for safety purposes

Highly durable exteriors (ceiling, floors, escalators)

Surfaces can be colored based on the product's preference

The color and quality of the aluminum surface stays the same after periods

Lustre and an authentic metallic sheen

All of these benefits make you think that it is indeed important to keep your metal protected from corrosion, not only that you can make the most of your devices but also make sure that it lasts longer.

What Can We Provide You

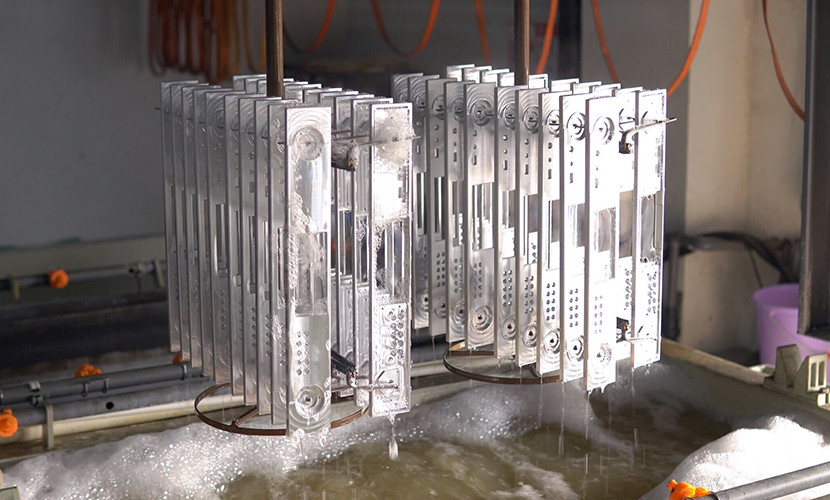

Overall, in YONGU we treat our aluminum alloys with sandblasting and anodization to further protect the metal from corrosion. Aside from the excellent anti-corrosion properties of aluminum itself, it can also be used as a good heat dissipator. Another excellent development we made here in YONGU is the creation of our M Series, wherein aluminum enclosures are protected with IP68, the highest protection for industrial appliances. The M Series has weatherproof and waterproof resistance, with other properties that can withstand flooding. Go and have your products made by a professional aluminum manufacturer. Invest in protection for a durable product. Call us now.