NEMA vs. IP: What’s the difference?

The National Electrical Manufacturers Association (NEMA) establishes the standards for electrical equipment supplied in the United States. For electrical enclosures, NEMA standards feature numerical values that are sometimes followed by letters. The exact alpha-numeric combination establishes the product's NEMA rating, which relates to the environmental risks against which the cabinet must protect its inside.

IP enclosure standards are the worldwide standard. they originate from the European Committee for Electrotechnical Standardization (CENELEC). Although some American manufacturers may provide IP ratings for their goods, this information is primarily shown on electrical cabinets manufactured outside the United States.

Both of these standards outline the criteria for utilising an electrical cabinet, however, they differ. The challenge of comparing IP and NEMA ratings gets complex since each set of standards assesses unique criteria. The three digits in IP standards, for instance, reflect the level of protection against solids, liquids, and mechanical impacts. Greater values suggest a more durable cabinet.

The NEMA standards outline the cabinet's environment and the factors it protects against. A NEMA 3R versus an IP rating would suggest different situations. The 3R rating indicates that the inside is protected against dust, precipitation, ice, and snow, as well as accidental contact with electrical components. This classification is basically equivalent to an IP14, which provides protection against solid objects up to 50 millimetres in diameter and water penetration from any side.

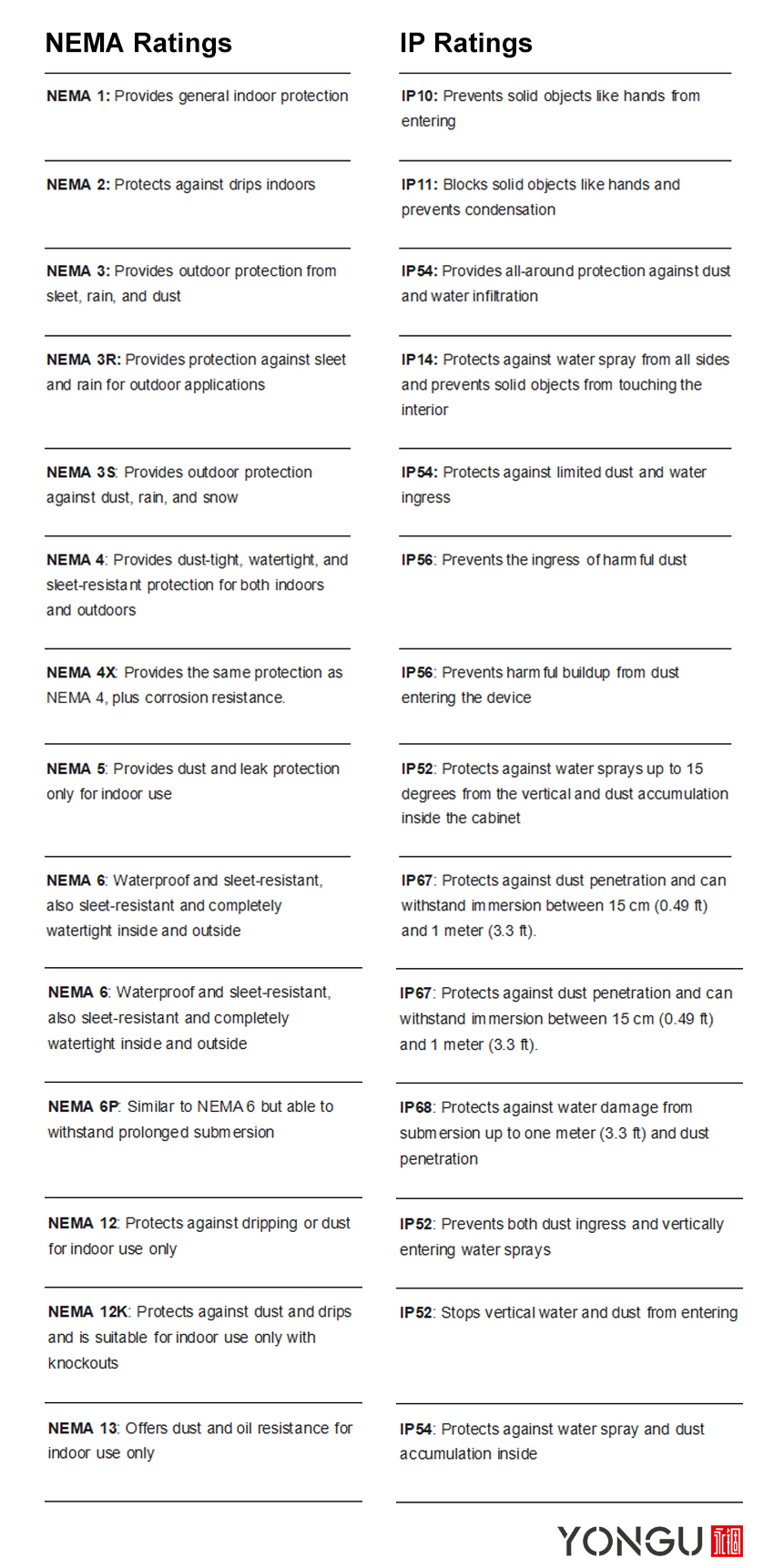

NEMA vs. IP Ratings

It is important to keep in mind the significant differences between NEMA and IP when comparing cross-reference tables. Despite their close similarity, NEMA and IP equivalencies should not be regarded as rules. The following are some NEMA ratings and their closest IP comparisons:

NEMA Enclosure Ratings

NEMA enclosure ratings provide manufacturers with a means to demonstrate the many locations and situations their cabinets can protect electrical interiors against. As shown in the table, the NEMA ratings indicate whether the product is intended for indoor or outdoor usage. Applications for ratings 1 through 6, 12 and 13 exist in nonhazardous environments. The enclosures with ratings between 7 and 10 have specialised use in hazardous environments, such as medical care, mining, and areas with potentially explosive chemicals nearby.Consider the enclosure's location and the climatic conditions against which the inside must be protected before applying NEMA ratings. Utilize these factors to determine the optimum rating for an enclosure's intended purpose.

Cabinets with NEMA ratings of 3 or 4 are among the most popular solutions since they are suitable for outdoor applications and can endure a variety of weather conditions. Enclosures of type 3R provide adequate protection from rain and sleet in the open air. Due to the unpredictability of the weather in the Northeastern United States, such protection is essential for all outdoor electrical equipment and housing.

NEMA rating 4X, with its waterproof sealing, dust protection, and corrosion resistance, is the superior choice for more complete protection that may be used inside and outdoors. This kind of enclosure can even withstand the extreme conditions of an offshore location.

IP Enclosure Ratings

Although more prevalent among overseas manufacturers, IP enclosure ratings may nevertheless appear on certain electrical cabinets built in the United States. To interpret these evaluations, you must be aware that they may include two or three digits. These relate to how solids, liquids, and impacts are protected. However, for certain devices that lack a specified rating, X is substituted for the number.The first value indicates the size of the objects that cannot enter the cabinet. Zero means that there is no protection. Low values indicate that the cabinet prevents hands but not dust from entering. The maximum value for this identifier, six, denotes total protection against dust entering the enclosure.

The next digit in the value indicates liquid ingress protection. These numbers range from 0 to 8 and represent the increasing extent of protection against water entering the enclosure. A zero indicates that there is no water protection, but an eight prevents water from entering even when the enclosure is submerged in water under pressure.

The third number indicates the mechanical impact resistance of the container. This may be present in certain devices since the majority of codes do not need its existence. As with previous numbers, zero equates to no protection for this third value. The values rise to six, avoiding harm from a 5 kg (11 lb) object dropped from a height of 40 centimetres (1.31 ft).

Heavy machinery, industrial plants, and underwater and outdoor applications require IP67/IP68 enclosures. We would recommend using YONGU enclosures as they have a wide variety of IP-rated enclosures with flexible customization options. These enclosures come in two series: L and M series.

YONGU L Series: Durable enclosures rugged enough for indoor or outdoor applications. L Series include around 24 different models, including

- Outdoor Electrical & Water Proof Boxes

- Waterproof Plastic Enclosures

- Waterproof Electrical Enclosures

- IP67 Aluminum Boxes

- Waterproof Electrical Junction & Power Boxes

- Weatherproof Electrical Enclosures

- Waterproof Metal Junction Boxes

- Waterproof Box for Boat

- Waterproof Battery Boxes

- Automotive Waterproof Electrical Junction Boxes

- Waterproof Connection Boxes

- Waterproof PCB Boxes

- Waterproof Switch Boxes

- Waterproof Underground Electrical Junction Boxes

M Series include around 11 different models, including

- IP67/IP68 Aluminum & Waterproof Boxes

- weatherproof electrical boxes

- outdoor electrical junction boxes

- waterproof junction boxes

- outdoor electronic boxes

Both M and L series have the following properties in common.

- Rugged and robust for heavy-duty use.

- Maintaining waterproof and dustproof functioning is made easier by using a distribution

- Dispensing ring

- Diecast aluminium housing that is resilient to socks

- The unfinished interior surfaces can be used to achieve conductivity

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].