Industrial settings demand robust, resilient materials to safeguard sensitive equipment from harsh conditions. Anodized aluminum enclosures have emerged as a cornerstone in industrial design, offering a multitude of benefits that elevate their utility and longevity in such environments.

Definition and Purpose

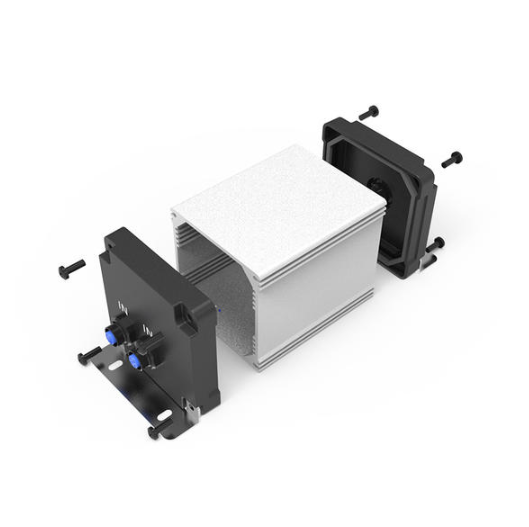

Anodized aluminum enclosures are protective casings fabricated from aluminum subjected to an electrochemical process known as anodizing. This process creates a durable, corrosion-resistant surface, making these enclosures ideal for industrial use.

5 Benefits of Investing Anodized Aluminum Enclosures

In this section, the author would list the main benefits of investing anodized aluminum enclosures.

1. Durability and Strength

Anodized aluminum enclosures are renowned for their exceptional durability and strength, making them an ideal choice for safeguarding sensitive equipment in industrial settings.

The process of anodization enhances the natural properties of aluminum by forming a protective oxide layer on its surface.

This layer significantly increases the material's resistance to wear and tear, ensuring longevity even in harsh conditions.

This durability is pivotal in industrial environments prone to mechanical stress, impact, or abrasive elements.

Anodized aluminum's robustness allows it to withstand rough handling, impacts from machinery, and exposure to abrasive particles without compromising its protective capabilities.

As a result, equipment housed within these enclosures remains shielded from potential damage, contributing to increased operational reliability and minimized downtime.

The process of anodization enhances the natural properties of aluminum by forming a protective oxide layer on its surface.

This layer significantly increases the material's resistance to wear and tear, ensuring longevity even in harsh conditions.

This durability is pivotal in industrial environments prone to mechanical stress, impact, or abrasive elements.

Anodized aluminum's robustness allows it to withstand rough handling, impacts from machinery, and exposure to abrasive particles without compromising its protective capabilities.

As a result, equipment housed within these enclosures remains shielded from potential damage, contributing to increased operational reliability and minimized downtime.

2. Corrosion Resistance

The anodizing process creates a dense and durable oxide layer on the surface of aluminum, imparting remarkable corrosion resistance. This resistance to corrosion is particularly crucial in industrial settings where exposure to moisture, chemicals, or corrosive elements is prevalent.

Anodized aluminum enclosures effectively protect sensitive equipment from the detrimental effects of corrosion, ensuring their functionality and structural integrity over extended periods.

By preventing corrosion-induced damage, these enclosures maintain their protective properties, preserving the equipment housed within and reducing the need for frequent replacements or repairs. This resistance to corrosion contributes significantly to the reliability and longevity of equipment in diverse industrial applications.

Anodized aluminum enclosures effectively protect sensitive equipment from the detrimental effects of corrosion, ensuring their functionality and structural integrity over extended periods.

By preventing corrosion-induced damage, these enclosures maintain their protective properties, preserving the equipment housed within and reducing the need for frequent replacements or repairs. This resistance to corrosion contributes significantly to the reliability and longevity of equipment in diverse industrial applications.

3. Electrical Insulation Properties

Anodized aluminum's oxide layer acts as an effective insulator, providing electrical insulation properties that are vital in industries reliant on electrical equipment.

This insulation capability prevents electrical conductivity through the enclosure, reducing the risk of short circuits or interference that could damage sensitive electronic components.

In industrial settings where electrical equipment is prevalent, such as control panels or power distribution units, anodized aluminum enclosures offer a secure environment that ensures the safety and reliability of electrical systems.

The insulating properties of these enclosures contribute to enhanced safety standards and reduced risks of electrical failures, supporting uninterrupted industrial operations.

This insulation capability prevents electrical conductivity through the enclosure, reducing the risk of short circuits or interference that could damage sensitive electronic components.

In industrial settings where electrical equipment is prevalent, such as control panels or power distribution units, anodized aluminum enclosures offer a secure environment that ensures the safety and reliability of electrical systems.

The insulating properties of these enclosures contribute to enhanced safety standards and reduced risks of electrical failures, supporting uninterrupted industrial operations.

4. Thermal Stability

Anodized aluminum exhibits impressive thermal stability, maintaining its structural integrity even when exposed to extreme temperatures. This attribute is particularly valuable in industrial environments characterized by high heat or fluctuations in temperature.

Industries like foundries, manufacturing plants, or aerospace facilities benefit from the thermal stability of anodized aluminum enclosures. These enclosures provide a protective barrier that shields equipment from the adverse effects of heat, ensuring consistent performance and preventing structural degradation even in demanding thermal conditions.

Industries like foundries, manufacturing plants, or aerospace facilities benefit from the thermal stability of anodized aluminum enclosures. These enclosures provide a protective barrier that shields equipment from the adverse effects of heat, ensuring consistent performance and preventing structural degradation even in demanding thermal conditions.

5. Lightweight yet Sturdy

Despite its robustness, anodized aluminum remains lightweight, facilitating ease of handling, transportation, and installation in industrial settings. This characteristic is advantageous in scenarios where mobility or frequent repositioning of equipment is necessary.

The combination of strength and lightweight properties makes anodized aluminum enclosures a preferred choice for industries seeking durable yet manageable solutions.

They offer the structural integrity required for protection while allowing for flexibility in installation and reconfiguration without compromising their protective capabilities.

The combination of strength and lightweight properties makes anodized aluminum enclosures a preferred choice for industries seeking durable yet manageable solutions.

They offer the structural integrity required for protection while allowing for flexibility in installation and reconfiguration without compromising their protective capabilities.

Conclusion

These detailed benefits underscore the significance of anodized aluminum enclosures in industrial settings, portraying their role in ensuring equipment durability, reliability, and operational continuity amidst challenging environmental conditions.

Their remarkable properties offer a safeguarding haven for sensitive equipment, paving the way for enhanced productivity, reduced maintenance costs, and prolonged equipment lifespan.

Their remarkable properties offer a safeguarding haven for sensitive equipment, paving the way for enhanced productivity, reduced maintenance costs, and prolonged equipment lifespan.