APPLICATIONS FOR INSTRUMENT ENCLOSURES

Businesses increasingly depend on a linked chain of devices to promote efficiency and decision-making as the business IoT sector continues to rise. Because of this, it is essential to maintain a robust chain of command. Enclosures are built to give the highest level of security possible, ensuring that data is never interrupted.

Instrument enclosures are utilized in various settings, from the pharmaceutical and medical industries to testing and monitoring systems. Desktop and portable enclosures are vital to the smooth operation of crucial electronic instrumentation instruments because they provide dependable protection. Instrument enclosures have a wide range of uses in the scientific field. These applications need reliable security for delicate instruments, whether housed in elegant enclosures for laboratory equipment and control panels or robust instrument enclosures for testing and monitoring field devices.

Instrument enclosures may operate in various conditions while remaining calm and efficient with the correct venting system. Any instrument junction box can benefit from the advice in the following paragraphs, regardless of the type of instrumentation it contains.

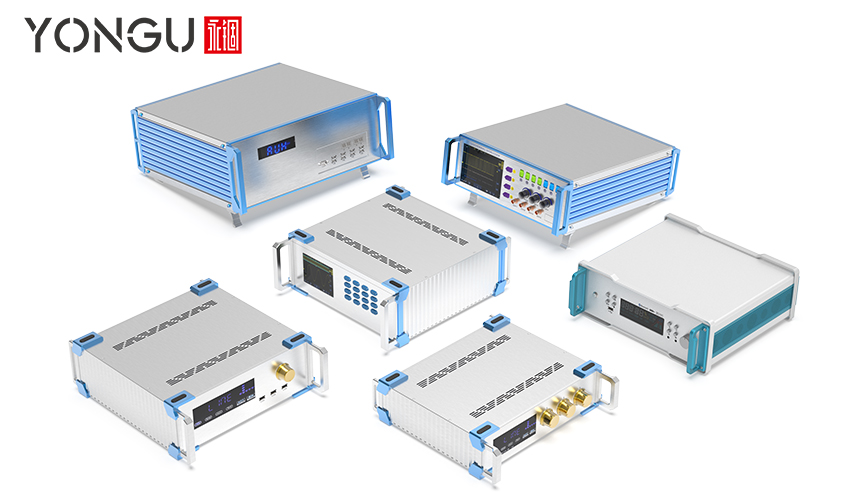

Several instrument enclosures are available to suit the extensive range of electronic instruments. If you're looking for long-term protection and shock absorption in a compact package, consider using YONGU custom-contoured enclosures.

Compact and durable enclosures can be used to contain desktop instruments, making them impervious to damage from spills or another unintentional touch. In addition to keeping the instruments close to the electronic equipment they operate, wall-mounted enclosures protect them from unwanted touches such as contact with dust, filth, splashing water, and the like.

Electronic devices facilitate precision work in scientific, engineering, medical, and technical disciplines. Instruments can be used in various ways, including control panels, operation switches, and more. There are a variety of components in an instrument enclosure depending on its intended use. Handheld enclosures can feature LCD screens that can be replaced using slide-on covers or a cutout. While wall-mounted enclosures commonly hang on DIN rail and may be pushed into position, desktop enclosures often incorporate vents, handles, locking mechanisms, and membrane keyboards.

Generally, they are used to store instruments like:

- Routers and modems

- Control boxes

- Rack-mounted data center equipment

- Radio transmitters

- Card readers

- Medical devices

- Hard drives

- Batteries and chargers

SOME POINTS TO CONSIDER FOR INSTRUMENT ENCLOSURES

Thermal Rise

From the materials of the enclosure to its size and surface area, your junction box's thermal management needs will take all of these elements into account.When working with massive, hot electronics, it's critical to employ precise calculations. Using heat transfer software or working with an enclosure maker is the best way to get the accuracy. If you're dealing with a situation where heat management is a crucial concern, enclosures are the best option.

On the other hand, most low-powered applications don't need such exacting math. For example, you may assess the heat dissipation capacity of your instrument enclosure and then select a solution that best fits your needs.

Moisture Management

It's also crucial to think about how you'll keep moisture from building up in your instrument junction box. Instrument enclosure moisture can have serious detrimental effects if allowed to build up.Moisture control is just as important as heat management when it comes to ventilation. A well-ventilated enclosure helps keep moisture out of the junction box. Vent plugs are a popular choice because of their ability to keep moisture out while allowing optimum ventilation.

Another technique to keep moisture from building up within your junction box is to use an enclosure with an IP68 waterproof rating.

Vents

Breather vents and soffit vent vents allow air to circulate freely through the instrument enclosure to equalize pressure and decrease condensation. The instrument enclosure is aired out, and the heat is dissipated when the colder air flows through it.These electrical enclosure venting attachments can prevent liquids and dust from getting inside the enclosure. There are no operational costs, which means they are also reasonably priced.

On the other hand, a drawback of breather and louvre vents is that they don't remove much heat. If your enclosure is not in a temperature-controlled environment, it is also challenging to estimate ambient temperature changes.

Cooling Fans and Blowers

Natural convection is the primary heat dissipation method employed by most low-power dissipators. On the other hand, high-power dissipations frequently utilize fans and blowers for forced ventilation.Fans can be used to transfer heat evenly in bigger sealed enclosures to avoid excessive heat concentrations in the enclosure. On the other hand, Circular fans are unable to disperse heat in enclosed enclosures because the heat has nowhere to go.

Circular fans can dissipate heat from open instrument enclosures, which are not large enough to merit a fan.

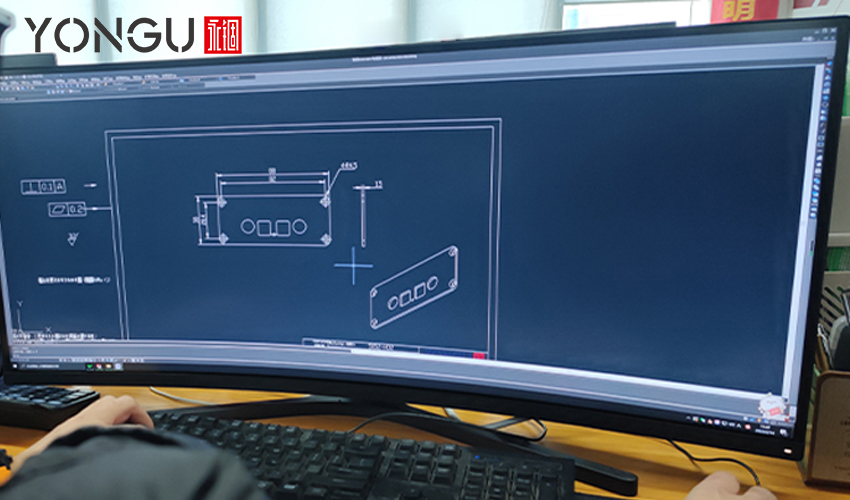

Additionally, CNC machining services to create machined holes for ventilation and venting accessories for CNC electronic boxes. The latest CAD/CAM automation technologies can aid for cuts of almost any form or size to any surface with high precision.We can cut according to your CAD specs to build a bespoke venting. Cutouts made with a custom CNC machine provide you with more creative freedom when it comes to aesthetics.

YONGU INSTRUMENT ENCLOSURES

Every aspect of our electronics enclosures is designed to add value to the client. Several of our enclosures' characteristics demonstrate this commitment:

- Wide variety of styles to choose from to meet practically any performance need

- Constructed from durable materials such as high-quality intruded aluminium

- Modern, eye-catching designs that convey the image you want to project

YONGU's aluminum extrusions are used to make desktop instrument enclosures for instruments. Each is made to exacting quality standards and comes with unique features and advantages. As a fast reference to our model series, below is a list of our A, B, D, F, and G of instrument enclosures:

Instrument Enclosure Series A, Series B & Series D

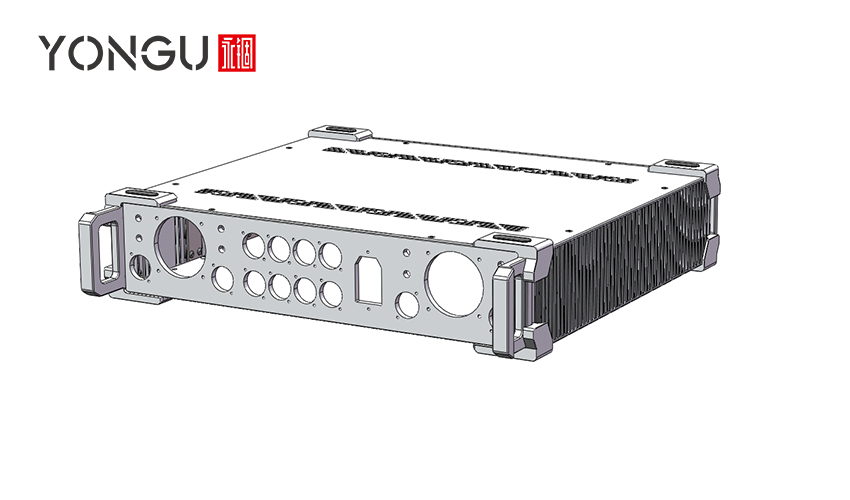

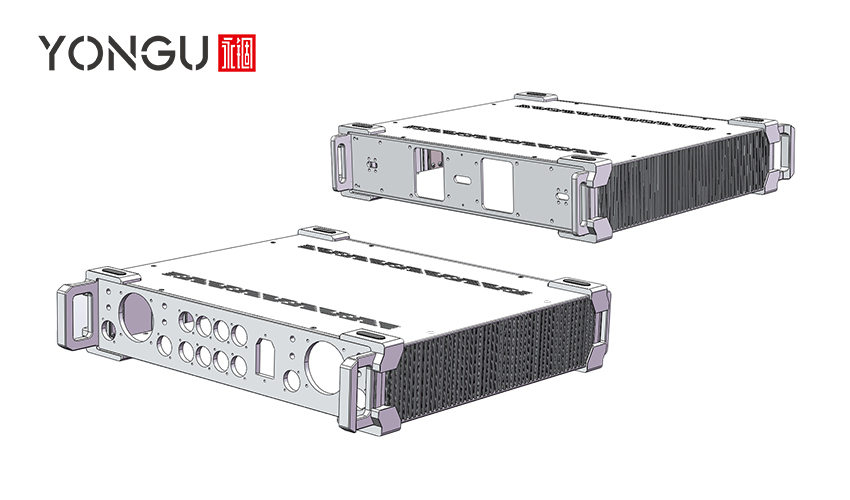

YONGU A01 260*2U Aluminum CNC Machining Case

Series A includes 12 Models of Aluminum CNC machining Enclosures.

YONGU B01 248*2U Electronic Enclosures

Series A includes 12 Models of Aluminum Electronic Enclosures.

YONGU D01 269*2U Instrument Enclosures

Series D includes 9 Models of Aluminum Electronic Enclosures with the following features.

- High-tech desktop and portable enclosures in nine standard sizes, all of which have ventilation

- A clean, modern look with no visible screws

- Snap-on front trims conceal the case and front panel fastening screws for a clean look.

- Extrusion case body

- Anodized aluminium front panel (accessory) – recessed for protection of keypads, displays, etc

- All case panels are supplied with M4 threaded pillars for earth connection on the backside of each panel.

- Aluminum pads can be anti-slip and anti-moisture, protecting internal components from damage.

Series A & B has the following features in common

- Thickened panel

- Customizable precision processing

- Handles with the high load-bearing capability

- Enclosures with aluminium alloy shielded corners are more crash-resistant.

- Easy-to-install side panels with a modular design.

- Customizable In addition to increasing the effectiveness of heat dissipation and giving the cabinet an air of industry and design, the dimensions, cuts, hole drilling, surface treatment, printing, and various colors contribute to improved heat dissipation.

- You may choose from various anodizing colors and 6mm front and rear plates for the entire set.

- Front-facing screws can't be seen since they use a particular model that hides them. This increases the safety of your equipment.

- Rubber foot pads can be slip-proof and moisture-proof, protecting internal components from damage.

Series A, B & D has the following features in common.

- CNC processing creates the front, rear, and side corners, giving you a sense of modernity.

- Screws and rivets on the surface can be minimized using inner plates. Iron will be more durable than aluminium if they are the same thickness. This is advantageous when it comes to installing significant components.

- The dimensions, such as length, breadth, and height, are modifiable. The length can be adjusted or lowered in increments of 50mm or 100mm as a single unit of measurement.

Instrument Enclosure SeriesF & Series G

YONGU F01 268*2U CNC Machining Case

Series F includes 8 Models of CNC machining Enclosures with the following unique features.

- Concise lines for visual designs

- Curve components to improve the sensation of quickness

- Color harmonizing is mainly centered on cold hues, conveying a sense of engineering and innovation

- Customizable Features like dimensions, slits and dings, hole drilling, finishing, printing, and CNC machining

- The front panels are curved to resemble an arch bridge in the design.

- You can use nuts to stabilize the display on the rear side because each panel is 6mm thick.

- The use of handles can disguise the screws on the surface.

YONGU G01 235*35*155 Custom Aluminum Enclosures

Series G includes 17 Models of custom aluminium enclosures with the following unique features.

- Custom aluminum enclosures, G01-G06, height is settled, width and length can be changed.

- G12-G17, rack mount case. 2U/3U/ can be chosen

- Integrated Custom Aluminum Instrument Cases

- Customizable width & length

- Can be rack-mounted and placed on the table

For further information and customized product of your requirements, pls follow our FACEBOOK for more updates and info: https://www.facebook.com/Foshan-Gof-Electronic-Machine-Co-Ltd-104706631749290

You can also contact us at +86 13326782625 or write us at [email protected].