The term "conductor" describes an element that can allow electrical current to flow through it, whereas "insulator" describes one that does not. The properties of semiconductors fall somewhere in between those of conductors and insulators. Semiconductors are used in the production of diodes, ICs, and transistors.

The intensity of exposure by infrared, ultraviolet light, or X-rays, as well as the current or voltage provided to a control electrode, can all cause changes in conductance. Dopants are impurities that may be introduced into a semiconductor to alter its characteristics.

WORKING OF SEMICONDUCTOR

Multiple materials are often crystallized together to form semiconductors. Users need an understanding of atoms and the organization of electrons inside atoms to make sense of semiconductors. An atom's electrons form stacks or shells. The phrase "valence shell" refers to the outermost layer of an atom's structure.

The electrons in this valence shell make bonds between atoms. Covalent bonds are a specific kind of chemical bond. The valence shell of conventional conductors consists of a single electron. Compared to metals, semiconductors generally have a valence shell with just four electrons.

But if neighbouring atoms share the same valence, the electrons can pair up. When it occurs, atomic formations, known as crystals, form. Such crystals, most often silicon crystals, are used to fabricate semiconductors.

TYPES OF SEMICONDUCTOR

There are two distinct kinds of semiconductors: intrinsic and extrinsic.

Intrinsic Semiconductors

An intrinsic semiconductor is a substance with a high electrical conductivity at the atomic level. The most common intrinsic semiconductors are made of either pure germanium or silicon. These materials are insulators down to extremely low temperatures but become conductors over a certain threshold.

Some electrons will travel across the lattice due to collisions when the temperature increases. The ability to conduct electricity directly results from the presence of free electrons and holes in the material.

Extrinsic Semiconductors

Doping with particular impurities so that electricity may be conducted through it yields a material with the characteristics of an extrinsic semiconductor. Doping refers to the process of introducing impurities to a semiconductor. We cannot often use intrinsic semiconductors due to their weak conduction characteristics in electrical devices. To improve their conductivity, we introduce impurities into intrinsic semiconductors.

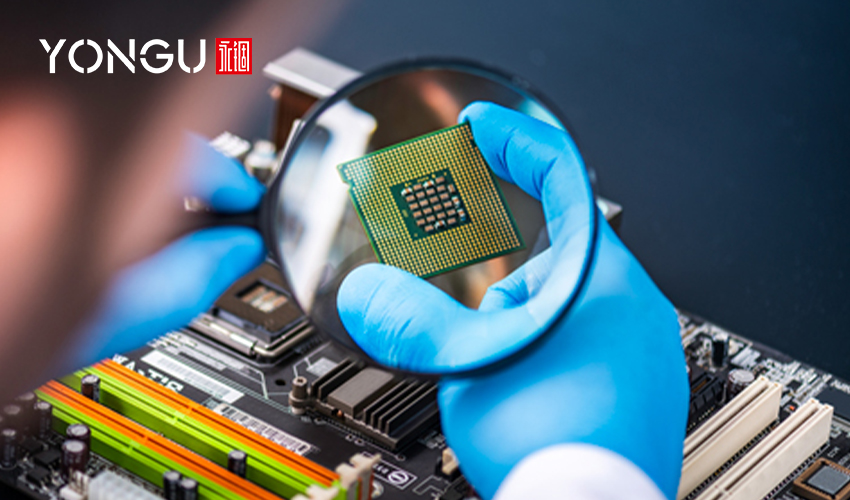

APPLICATIONS OF SEMICONDUCTORS

Now that we know how semiconductors work let's learn why they're so important. Almost every electrical product on the market today relies on semiconductors. We couldn't function as a community without them.

They are perfect for a wide variety of applications owing to their dependability, small size, low cost, and the ability to regulate power flow through them. Semiconductors are used in many electronic devices, including transistors, diodes, photo sensors, microcontrollers, and integrated circuits.

USES OF SEMICONDUCTORS IN EVERYDAY LIFE

- Semiconductor devices are utilized to create temperature sensors, which are then integrated into 3D printers.

- In microchips and autonomous vehicles.

- Employed in many digital gadgets like calculators, solar panels, laptops, and more.

- Semiconductors are employed in producing electrical circuit switches like the transistor and MOSFET.

Semiconductor materials are used to create transistors and other regulating devices utilized in microprocessors, which are then used to regulate the functioning of spacecraft, trains, robots, etc.

IMPORTANCE OF SEMICONDUCTORS

Some of the benefits of semiconductors that make them so widely applicable have been explored.

- Their compact size makes them easily transportable

- They consume less energy from the power source and are resilient to shock.

- The average lifetime is significantly higher.

- There is no operational noise when using them.

Thermal losses from power semiconductors can range from a few watts to several kilowatts and must be eliminated. The heat generated by power semiconductors necessitates careful thermal control; hence their electronic enclosures are made to be attached to heatsinks. The manufacturer usually lists the safest temperature for using special equipment electronic enclosures must be present to adequately cool semiconductors to prevent this temperature from being surpassed.

Manufacturers frequently built motors and other electro-mechanical systems with insulating temperature ratings that surpassed 130 degrees Celsius before the widespread adoption of electronics. High temperatures within project enclosure box were not a severe problem. It took many decades for power electronics and, by extension, semiconductors to become widespread with the introduction of transistorized electronic drives in the 1980s. Sadly, many engineers falsely thought these gadgets were as reliable as others. So, aluminum enclosure box for semiconductors with a suitable cooling system are crucial.

Several cooling methods are available to prevent semiconductors from overheating, and their selection is based on the electronics enclosure size and heat load. Increasing airflow using cooling fans is the quickest way to lower the temperature within the electronics enclosure. The temperature within the enclosure will rise slightly due to the method's reliance on the air outside. It is not suggested for use in high average temperature situations or severely loaded aluminum enclosure box.

For optimal temperature regulation of semiconductor-based equipment, a sealed electronics enclosure equipped with an atmospheric heat exchanger, air-to-water thermal exchanger, or enclosure air conditioning system is recommended. Due to their low heat transfer efficiency, atmospheric heat exchangers are often replaced by electronics enclosure air conditioners.

YONGU ELECTRONICS ENCLOSURES

Don't hesitate to get in touch with us if you have any questions or need assistance locating an enclosure for electronics such as semiconductors. Because they construct and design high-quality electronic enclosures following your exact requirements, YONGU can effectively meet the lead time requirements you have set.

YONGU offers various models for heat dissipation of your electronics component, including semiconductors, among which few are mentioned here.

- YONGU Split Extruded Box H02 50*21mm

- YONGU Custom Plastic Cover Eletrical Box K22C 180*45mm

Following are their unique features, including

- Custom colours and finishes (anodizing, sandblasting, brushing) are available.

- Panels may be bent and cut to fit your needs.

- Extruded panelling can be added as an extra feature (flat, heatsink, stripe).

- Dimensions may be adjusted to any specification.

- Individualized venting through cut-outs.

- A design that effectively dissipates heat.

- Anti-slip feet are an option.

- Milling and Drilling of Specialized Holes

- NEMA and IP-rated safety standards.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].