Almost everyone has once wondered how one goes about plugging in a laptop, a digital gaming console, or perhaps a small refrigerator. A car battery can power these gadgets.

However, more is involved than just plugging something into the lighter and crossing your fingers. You'll need specialized equipment to accomplish this task because the battery's electrical current and the current these gadgets require are different. Using a power inverter can facilitate this.

POWER INVERTER BASICS

Direct current (DC) electricity is consistent and uninterruptible but only has a single direction for the electrical charge to go. However, alternating current (AC) electricity flows in both directions at once, giving rise to a sine wave shape with uniform peaks and troughs when seen using an oscilloscope.

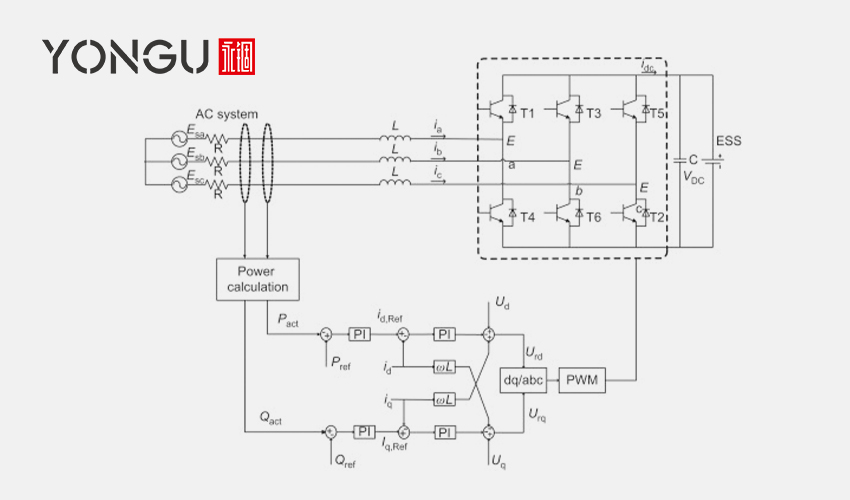

An inverter is an electronic circuit or device that converts direct current to alternating current. The end product's AC frequency can vary widely depending on the instrument employed. Filters are necessary to smooth out the wave so that it may be used by additional electrical equipment, as the oscillations created by them are rough.

Each device or circuit has unique input voltage, output voltage and frequency specifications, and total power handling. When connected to a DC source, an inverter converts the voltage and frequency of that source into AC.

An inverter can either only rely on electrical components, like a rotary device, or use both mechanical and electronic components. When converting, static inverters don't employ any revolving parts.

Most electronics can only function properly when supplied with AC power, as this is what is provided by the typical wall outlet. Low, regulated voltage is required for the proper operation of these gadgets. Stepping up or down AC power, or switching from one voltage to another, is simpler and more manageable than doing the same with DC power.

TYPES OF INVERTERS

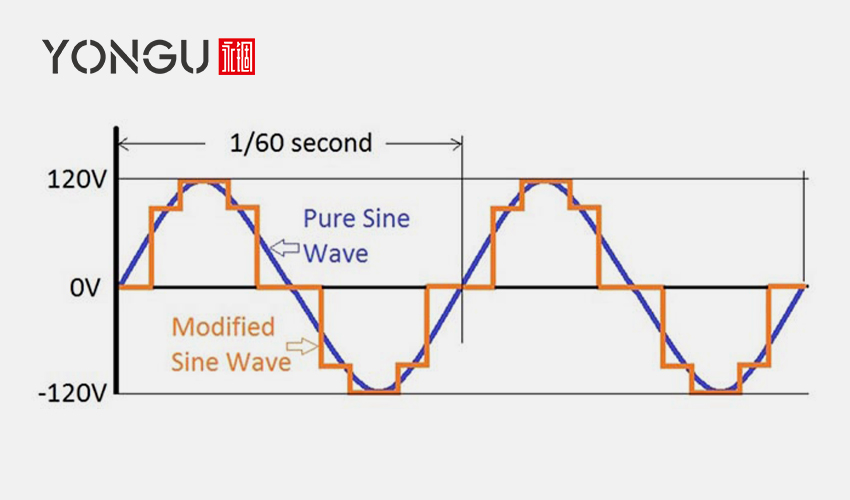

Pure sine waves, square waves, or modified sine waves are the three primary waveforms generated by most power inverters.

Square Wave Inverter

The most fundamental waveforms that an inverter can generate based on its circuitry, and it works well for relatively low-sensitive applications like illumination and heating systems.

Modified Sine Wave Inverter

Lighting and some power tools, which are less sensitive to electrical disturbances, can be safely and cheaply powered by modified sine wave inverters. Alternating current is simulated from direct current batteries using modified sine wave inverters.

Electric motors, compressors and other such loads are moderately inefficient when utilizing this power, since the power supply can't filter the improper AC voltage.

Sine Wave Inverter

In comparison to square wave and modified sine wave inverters, the waveform of a customer-grade sine wave inverter is smoother.

Inverters that create a pure sine wave are comparable to the electricity supplied by the grid. Your electronics and equipment will operate cooler and more effectively with this power supply. TVs, audio systems, and other sensitive electrical gadgets that rely on audio and video components will have clear audio and visual output. Chargers for cordless tools are safe for use with pricey batteries.

USES OF POWER INVERTER

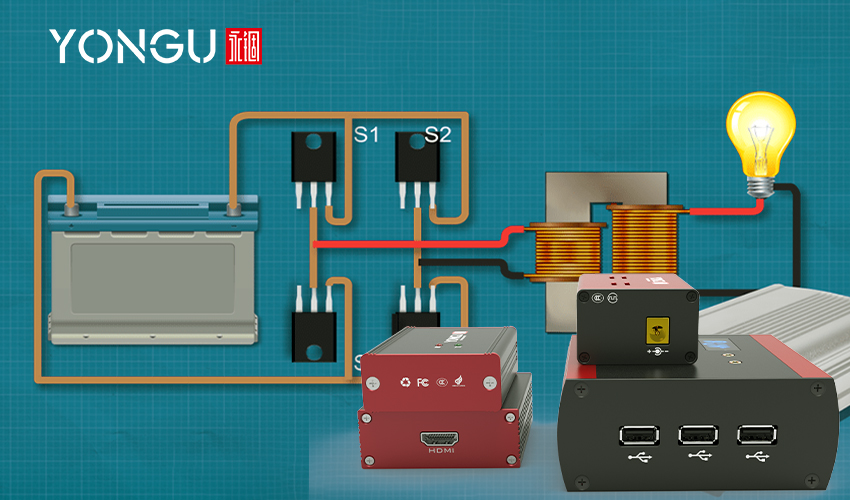

The most fundamental power inverters are often compact, rectangular devices that may be plugged straight into DC outlet on the vehicle's console. An inverter of this size can usually run a laptop computer, a mini TV, a mobile DVD player, or something comparable.

Since these gadgets don't require much energy to function, you can use them constantly while driving; you can even use them for half an hour to an hour when the car's engine is turned off, which is useful when camping or when there's a blackout at home.

Other power inverters provide jumper connections for direct battery connection. This kind is necessary to power more demanding devices, such as power tools at a distant work site or a giant TV. When working with bulky equipment, it might be helpful to hard-wire an inverter directly into the battery.

Larger inverters are required to transform DC electricity from solar panels or wind turbines into AC power suitable for household usage. This technology, known as a grid-tie inverter, connects to the electrical grid so that electricity may be transmitted through the same lines used by the utility company. Additionally, surplus energy may be sent back into the grid and sold to the power provider.

BENEFITS OF POWER INVERTERS

Energy Saving

Power inverters are very helpful in fan and pump applications. By managing motor rotation, inverters may minimize energy usage by 20-50%, making them superior to dampers and on/off switches. It's like decelerating an automobile. To decelerate without using the brakes, softly tap the accelerator.

Soft Starters

The motor is kicked off by a low-frequency power supply from an inverter or AC drive. Over time, it steadily turns up the engine and frequency to the set point. Acceleration and deceleration may be adjusted at will, making them perfect for use on conveyor belts and escalators to prevent cargo from falling off.

Controlled Starting Current

Starting an AC motor requires approximately seven to eight times the full-load current. Since the power inverter decreases the beginning current, the motor requires less frequent rewinding and lasts longer.

Reduced Power Line Disturbances

If an AC motor is started across the line, it can put a significant load on the power grid and lead to a drop in voltage. When a huge engine starts up, it can cause sensitive devices like computers and sensors to trip. If there is a voltage drop, the inverter will cut power to the motor rather than tripping.

Quickly Changes the Direction of Rotation

Modern inverters or variable frequency drives can withstand abrupt starts and stops. We can change the rotation instruction with a minimal current. The inverter drive allows for precise regulation of the number of rotations.

Simple Installation

Modern electrical inverters include pre-programming. Auxiliary power controls, data lines, and motor connections are all pre-installed in a motor. The contractor's only task is to connect the cable to the AC drive's power source.

Adjustable Torque Limit

An inverter can prevent motor failure by precisely regulating the torque applied to the machine. A machine jam, for instance, will cause the motor to keep turning until the overload switch is activated. To keep the motor from overheating, we can program the AC drive to restrict the amount of torque it applies to the motor.

Elimination of Mechanical Drive Components

Without additional equipment like speed-increasing or -reducing gearboxes, a power inverter can supply the exact range of speeds required by the load. It reduces the need for upkeep and the size of the building.

WHY DO INVERTERS NEED ENCLOSURES?

The inverter is responsible for changing the power being generated into usable electricity. Without adequate protection from extreme temperatures and environmental variables, the inverter's performance will decrease, and the end user will have to pay the price. There is no universal method for protecting inverters from failure, as each application has specific requirements.

Consumers and operators should be aware of this reality when shopping for a power inverter and prepared to ask the manufacturer pertinent questions about airflow/cooling, environmental protection, operations and maintenance, and electromagnetic interference (EMI) shielding. Sheet metal and non-metal enclosure manufacturers should design enclosures so the inverters can keep delivering power for longer and better.

YONGU ELECTRONIC ENCLOSURES

Electronic enclosures for inverter protection is designed and manufactured by YONGU, an industry leader in china aluminium parts manufacturer. Whether you need thousands of aluminium alloy products for a rollout or just a few to get things rolling on a big, long-term project, our metal enclosures are flexible and adaptable.

One of the products of YONGU is YONGU Great Power Lifepo4 Solar 48V Battery Hybrid Inverter Aluminum Alloy Electronic Enclosure H38 234*80.6mm.

It includes the following features:

- Two-piece body with easily removable belly plate for easy access to the top interior of the enclosure

- General Purpose, EMI Shielded or Heat Dissipation Options

- Sandblast and brushed surface finishing options, anodized color

- PCB boards mount horizontally by sliding into internal slots extruded into the enclosure body

- Customization options for length, milling, and thickness

- Silkscreen or engraving option

YONGU's state-of-the-art on-site and data management, which adheres to a comprehensive method for milling and carving, allows the firm to meet stricter criteria for production and finishing.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].