Waterproof enclosures are a vital component in safeguarding equipment from the detrimental effects of water exposure. In essence, they are specialized casings designed to prevent water ingress, thereby ensuring the integrity and functionality of enclosed equipment. Understanding their significance in equipment protection is paramount for maintaining operational efficiency across various industries.

Definition of Waterproof Enclosures

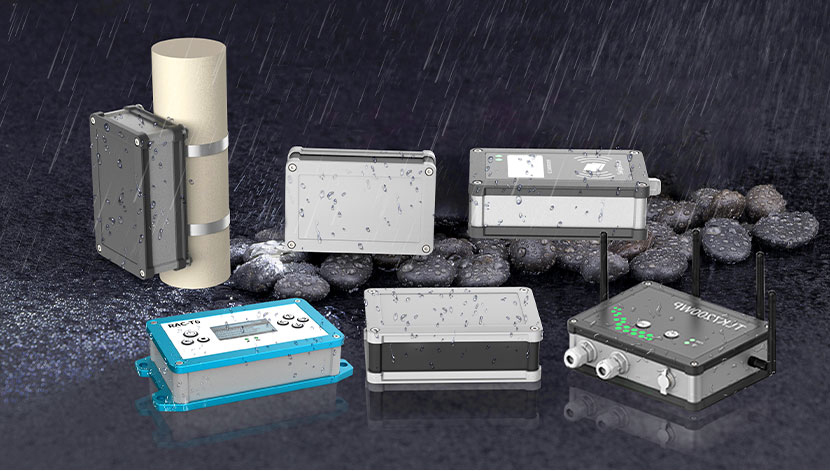

Waterproof enclosures, often referred to as waterproof cases or housings, are protective coverings engineered to shield electronic or mechanical equipment from water damage. These enclosures feature robust construction and sealing mechanisms to create a watertight barrier, safeguarding sensitive components from moisture, humidity, and other environmental hazards.

Importance of Waterproof Enclosures for Equipment Protection

In industries where equipment is exposed to challenging environmental conditions such as moisture, rain, or submersion, waterproof enclosures play a critical role in preventing corrosion, short circuits, and other water-induced malfunctions. By preserving the integrity of enclosed equipment, waterproof enclosures ensure consistent performance and minimize downtime, ultimately contributing to enhanced productivity and operational reliability.

Why Choose Metal Enclosures?

Metal enclosures, crafted from materials like aluminum or stainless steel, provide superior strength and resistance to corrosion, making them ideal for demanding industrial environments or outdoor installations subject to extreme weather conditions. Their robust construction ensures reliable protection against water intrusion, making them a preferred choice for critical infrastructure and electronic instrumentation.

Factors to Consider When Choosing Waterproof Enclosures

Environmental Conditions

When selecting a waterproof enclosure, it's crucial to assess the specific environmental conditions in which the equipment will operate. Factors such as temperature fluctuations, exposure to UV radiation, and the presence of chemicals or corrosive agents can influence the choice of enclosure materials and sealing methods to ensure optimal protection against water ingress.

Size and Dimensions of Equipment

The size and dimensions of the equipment will dictate the appropriate size and configuration of the waterproof enclosure. It's essential to choose an enclosure that provides adequate space for accommodating the equipment while allowing for proper ventilation and cable management. Additionally, consideration should be given to future expansions or modifications that may require additional space within the enclosure.

Degree of Waterproofing Required

Different applications may necessitate varying levels of waterproofing, ranging from water-resistant enclosures suitable for splash protection to fully submersible enclosures capable of withstanding prolonged immersion underwater. Assessing the degree of waterproofing required based on the equipment's exposure level and operating environment is crucial for ensuring reliable protection against water ingress.

Accessibility for Maintenance

Ease of access for maintenance and servicing is another critical factor to consider when selecting a waterproof enclosure. Ensuring that the enclosure allows for convenient access to internal components, connectors, and controls simplifies routine inspections, repairs, and upgrades, thereby minimizing downtime and optimizing operational efficiency.

Benefits of Waterproof Enclosures

Protection Against Water Damage

The primary benefit of waterproof enclosures is their ability to protect enclosed equipment from water damage, thereby mitigating the risk of corrosion, short circuits, and other moisture-related malfunctions. By creating a barrier against water ingress, waterproof enclosures safeguard sensitive electronic components and mechanical assemblies, ensuring uninterrupted operation in challenging environmental conditions.

Extended Lifespan of Equipment

By shielding equipment from water and moisture, waterproof enclosures contribute to extending the lifespan of enclosed devices, reducing the frequency of repairs and replacements. This not only helps to optimize the return on investment but also enhances the reliability and performance of critical systems, ensuring continuous operation and productivity.

Maintenance of Performance in Harsh Conditions

Waterproof enclosures enable equipment to maintain optimal performance even in harsh environmental conditions, such as heavy rain, high humidity, or exposure to corrosive substances. By preventing water ingress and environmental contaminants, these enclosures ensure consistent operation and reliability, even in the most demanding industrial or outdoor settings.

Compliance with Industry Standards

Many industries have stringent regulatory requirements and standards pertaining to equipment protection and safety. Utilizing waterproof enclosures that meet or exceed these standards not only ensures compliance but also provides assurance of quality and reliability. Whether it's for medical devices, automotive electronics, or outdoor signage, choosing certified waterproof enclosures demonstrates a commitment to meeting industry-specific requirements and ensuring customer satisfaction.

Tips for Proper Installation and Maintenance

Ensure Proper Sealing

Proper installation and sealing of waterproof enclosures are critical to their effectiveness in preventing water ingress. Follow manufacturer guidelines and recommendations to ensure a secure and watertight seal around the enclosure openings, including cable glands, vents, and access panels. Regularly inspect seals for signs of wear or damage, and promptly replace any compromised seals to maintain the integrity of the enclosure.

Regular Inspection and Cleaning

Routine inspection and cleaning of waterproof enclosures are essential for identifying potential issues and maintaining optimal performance. Inspect the enclosure for signs of damage, corrosion, or accumulation of debris that could compromise its effectiveness. Clean the enclosure regularly using mild detergent and water, avoiding abrasive cleaners or solvents that may damage seals or enclosure materials.

Use of Desiccants or Dry Storage Cabinets

In environments with high humidity or moisture levels, consider using desiccants or dry storage cabinets to absorb excess moisture and maintain a dry environment within the enclosure. Desiccants such as silica gel packets or moisture-absorbing pads can help prevent condensation and moisture buildup, reducing the risk of water damage to enclosed equipment.

Monitoring Environmental Conditions

Implementing a system for monitoring environmental conditions, such as temperature and humidity, can provide early warning of potential water ingress or environmental hazards. Utilize sensors and monitoring devices to track environmental parameters within the enclosure and alert operators to any deviations from acceptable levels. This can help facilitate proactive maintenance and intervention, allowing for timely corrective actions to prevent water damage or equipment malfunction.

Conclusion

In a world where equipment reliability is paramount, investing in quality waterproof enclosures is not just a precautionary measure; it's a strategic imperative for sustaining operational excellence and mitigating risks associated with water damage.

So, whether it's protecting sensitive electronics in a marine environment or safeguarding industrial machinery from the elements, the importance of waterproof enclosures in keeping equipment safe and dry cannot be overstated. By prioritizing equipment protection through the use of waterproof enclosures, organizations can fortify their resilience and ensure business continuity amidst the unpredictable forces of nature.