When designing electronic enclosures for electrical and electronic devices, you barely see a standard solution that is versatile to a variety of electronic and electrical devices. Our designers and engineers usually select their components in accordance with the required specification and specific functions of the devices. The electronics enclosure materials are also no exception. It’s very essential to know the attributes, strengths, and weaknesses of each material. The enclosure is the director factor affecting the protection of devices. On this page, we’ll guide you through a quick introduction to a variety of the materials of the enclosures. Plus, we also talk about their application.

Some Factors You Need to Consider (Before Design)

As above mentioned, the selection of the components should follow the specific functions of the devices. Therefore, it’s necessary to figure out what’s your device’s application before designing. Here are the following factors you need to consider.

Do your devices need to withstand chemical or saltwater corrosion?

What kind of weather conditions will your device encounter (snow, rain, or sleet)?

Do your devices need to equip EMI/RF shielding?

Do your devices need to get the machined cutouts?

What kind of ingress protecting rating will your device need to have (such as IP rating or NEMA rating)?

……

After considering these problems, it’s time to consider deciding the material issues. Here I will list the typical materials of the enclosure to let you briefly understand the design of the electronics or electrical enclosures.

Do your devices need to withstand chemical or saltwater corrosion?

What kind of weather conditions will your device encounter (snow, rain, or sleet)?

Do your devices need to equip EMI/RF shielding?

Do your devices need to get the machined cutouts?

What kind of ingress protecting rating will your device need to have (such as IP rating or NEMA rating)?

……

After considering these problems, it’s time to consider deciding the material issues. Here I will list the typical materials of the enclosure to let you briefly understand the design of the electronics or electrical enclosures.

Stainless Steel

Stainless steel is a kind of steel that alloys with some metals such as manganese and chromium. This alloying could improve its durability. Due to its characters, the stainless steel performs great resistance to scratching, pitting, staining, and corrosion. Furthermore, many grades of stainless steel are available. Each grade of stainless steel has its own advantages. 304 stainless steel is the most commonly used in the enclosure.

Application

Stainless steel enclosures are the most ideal choice for the devices which need to be protected by a high-durability enclosure. Stainless steel becomes the ideal material for outdoor weatherproof enclosure with its great performance in corrosion and weathering.

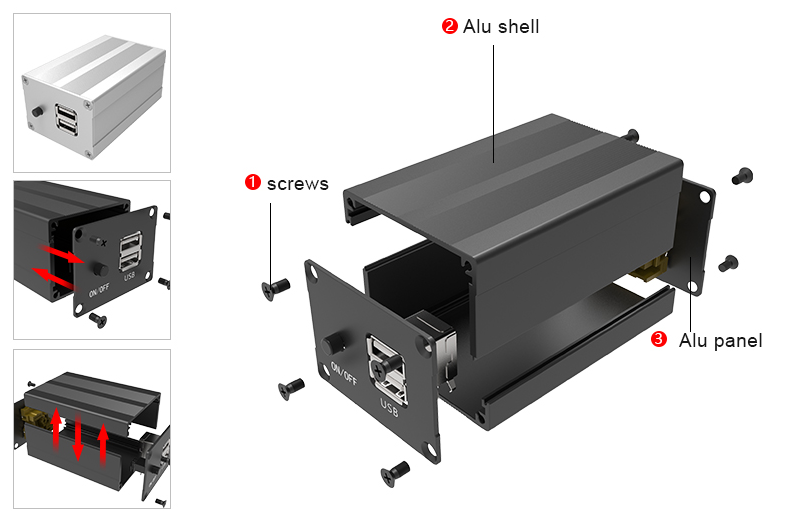

Aluminum

Aluminum is extracted from bauxite ore. It is hard, shiny, and lightweight. With its natural weather resistance, corrosion, and beautiful appearance, Aluminum is a highly recommended material for enclosures. Compared with stainless steel, aluminum has a lighter weight and is easier to cut with machining tools. With its natural RF shielding property, aluminum can block electromagnetic radiation from penetrating through the material.

Other Benefits of Aluminum Electronics Enclosures:

●High Rusting Corrosion Resistance

●Withstand High Temperature

●Not easy to swell of deform

●Environment friendly

●Great Ruggedness

●Withstand High Temperature

●Not easy to swell of deform

●Environment friendly

●Great Ruggedness

Applications of Aluminum Electronics Box

Aluminum enclosures are perfect choices for electronics devices that need rugged protection and a lightweight, attractive package. Also, because of its natural advantage, it is one of the most popular enclosures' materials which has the ability to block electromagnetic radiation.

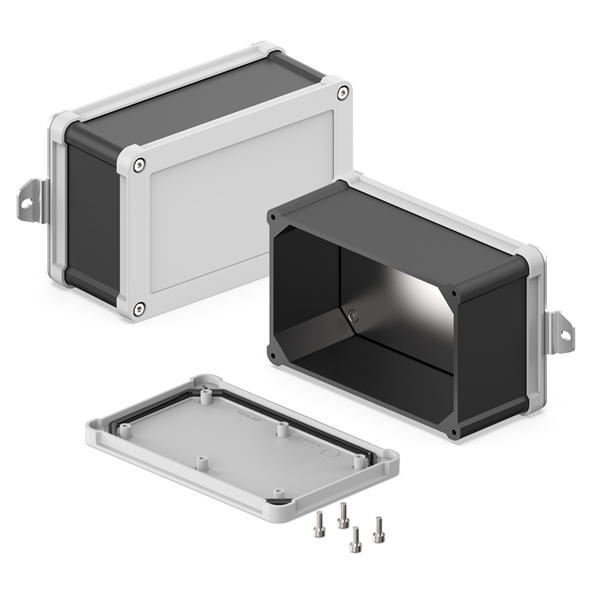

ABS

Acrylonitrile butadiene styrene (ABS) is a hard plastic that takes a great balance between durability and cost-efficiency. Furthermore, it’s also flame-retardant. The plastic enclosures usually used for ordinary electronic equipment. You can commonly find its figure in your daily life, especially in electronics products. ABS is easy to modify with custom machined cutouts.

Applications of Plastic Electrical Enclosure

ABS enclosure is a great protector for indoor electronics devices. With its low price, it becomes the ideal material for mass-produced devices. ABS is also the most popular enclosure material in the manufacturing industry.

Conclsion

Due to the specific applications of the electronic component enclosure, no matter what materials you choose to, you could consult the enclosure manufacturer that you trust to get your own ideal customized enclosure. The professional enclosure factory could offer a product that is better than your own made.