【Laser cutting】after invent not so long,Dozens of industries use it for a variety of scenarios.British use laser cutting apply for actual processing in1967s,let this technology has been more widely used.

Laser Cutting feature:

1.High precision cutting

a.Laser cutting notch are thin and narrow,The slits are parallel and perpendicular to the surface.

b.Laser cutting machines are controlled by CNC,so they can precise produce complex parts.

2.High efficiency cutting

a.Use 2000W laser power,The cutting speed of 2mm thickness stainless steel is 3.2m/min.

b.Because of the transmission properties of the laser,The whole cutting process all can realized CNC operation,only need to change CNC program,that It can used to cut parts for various shape.Two dimensional cutting can be carried out.It can also realize three-dimensional cutting .

c.The materials no need clamp and fix while laser cutting,it can save the fixture,also save the assist time.

3.High quality

Laser cutting can produce high quality notch and edge,reduce the needed for other finish machine processes.

4.Reduce material’s contaminating and wasted

Because of the smaller tolerance,The cut width is more narrower ,reduce the material wasted situation.

5.High safety in operation

a.The cutting process produce less noisy ,creating a quieter operating environment and reducing the risk of operator injury

B.The laser cutting process uses almost no mechanical components, so there is less risk of injury to the operator.

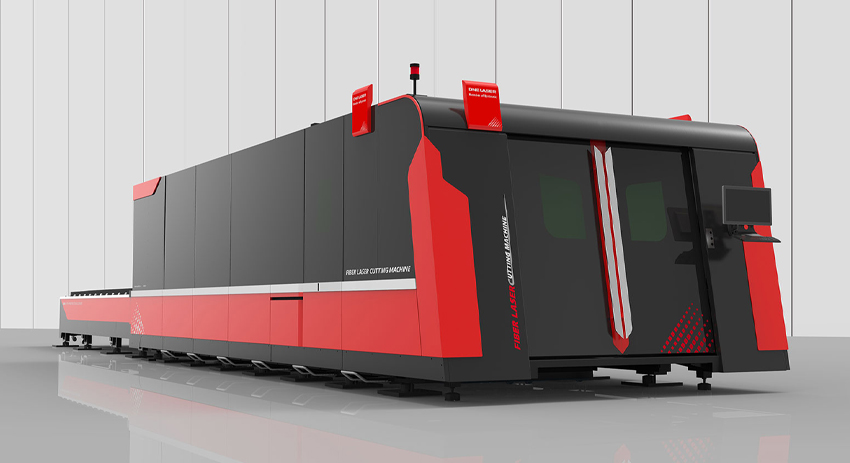

Yonggu enclosure use laser cutting craft produce for the product processes,then can high efficiency produce high quality products.