INTRODUCTION TO ROBOTICS

In the context of process technology, automation is a subcategory. "Automation" was invented by Ford Motor Company's engineering division in 1945 to describe the operations of their potential transference machines, which mechanically emptied castings from body presses and placed them next to machine tools. Automation is now used to denote any manufacturing process in which a machine is in charge and requires little or no human involvement to create fully automated. Robotics is one of several technologies that may help automate a manufacturing process, and it is becoming increasingly significant. Although there is no universal definition of "robotics," all definitions contain the conclusion that work is accomplished without or with minimal human participation. A physical machine is required in specific definitions, although the term "robot" can refer to software that performs the same functions as a real machine but without the physical manifestation.

The International Organization for Standardisation (ISO) definition of a robot:

“An automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes, which may be either fixed in place or mobile for use in industrial automation applications."

Reprogrammable: It means that the movements or auxiliary functions programmed into it can be altered without requiring any physical changes.

Multipurpose: It signifies having the capability of being converted to diverse applications by making adjustments to its tangible form.

Physical alterations: It refers to changes made to the mechanical structure or control system, except for modifications made to the programming discs, ROMs, and other similar components.

Axis: It indicates the direction used to determine the robot's mobility in a linear or rotational mode. This might be either clockwise or counterclockwise.

CLASSIFICATION OF ROBOTS

Service Robot: A robot that executes valuable activities for people or other devices but does not apply to industrial automation systems.

Domestic Service Robot: A service robot utilized for non-commercial activities, typically by amateur individuals, is referred to as a robot for domestic use. Examples of such robots include the autonomous wheelchair, the personal mobility support, and the pet exercise.

Professional Service Robot: A service robot for professional usage is operated by a fully trained operator and utilized for business purposes. Cleaners and delivery robots are only two examples of the many different types of robots used in the workplace or healthcare industry. When a robot or robot system has an operator, he or she is responsible for starting, monitoring, and stopping the robot's functioning.

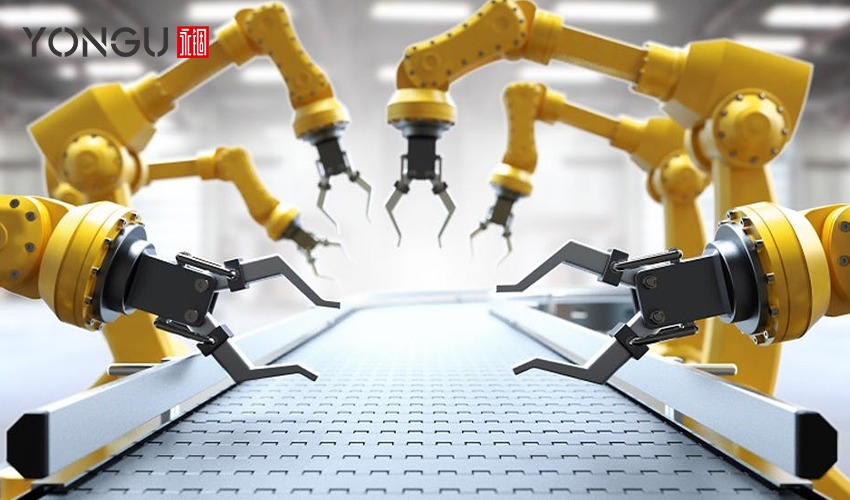

IMPROVED MANUFACTURING DUE TO ROBOTICS

The use of robots is essential to increasing production. Most robots have been used in manufacturing, where they can execute a wide range of manual jobs more quickly and smoothly than humans. From agriculture to logistics to hospitality, the usage of robots is extending to new areas due to technological advancements. Artificial intelligence is making robots more affordable, versatile, and autonomous.

The most significant shifts in production throughout history have all been brought about by technological advancements. We've now arrived at what's known as Industry 4.0, which began with the first steam-powered industrial revolution, electric power, and computers. Robots provide substantial value to manufacturers because of their safety, accuracy, and repetitive nature. All of which results in greater production line efficiency and ensure that firms remain competitive.

Gains in productivity may be accomplished using robotics using various approaches.

The following is a list of the most popular robot applications in manufacturing designed to boost productivity.

1. Safe Operations

More efficient operations are made possible by fewer downtimes and wasted hours due to unsafe working conditions. Robotics also has the advantage of enhancing worker safety. In the future, operators will no longer have to lift important things or do activities requiring repetitive motion. Robots can conduct these kinds of duties more safely than humans can.

Workers may be exposed to a wide range of chemicals and dangerous compounds in the workplace. There are several ways that robots may contribute to preserving human lives in risky workplaces, from handling harmful chemicals to radioactive material. Programming robots to take these materials precisely, the worst-case situation would be a technological repair rather than death or injury. As a result, robots are more suited to handle hazardous or temperature-sensitive commodities in warehouses. Mishandling by employees or during equipment transit can result in enormous losses for a company, which robotics might assist in minimizing.

2. Minimal Operation Time

Robots can produce more products even in minimal time. Without losing quality or quantity, automated operations may operate 24 hours a day and just require periodic downtime for maintenance - all without exhaustion! Human operators cannot compete with this in terms of speed and quality. In addition, robots seem more adaptable than people since changes may be incorporated into the automation software, rather than relying on human intervention. There is no requirement for training and a short turnaround time for product or production adjustments due to this method.

3. Cost-Effective Automation

Small companies may reap the benefits of automation without incurring the high prices of the past, thanks to a wide range of cost-effective automation options currently accessible. Automation can help small businesses with their supply chain and day-to-day chores more than ever before. With automation, companies may produce more items, emails, and other forms of communication. There is a tendency to see a better production in less time when using robots, whether they're simple machines or services that resemble robot assistants.

If you work in manufacturing, there are no constraints regarding robotics. Robots may be programmed to create according to a company's demands, whether making vehicle parts or toys.

4. Robotics Are Not Eliminating Jobs

In the long run, automating empowers humans to focus on more critical, value-added needs, maximizing their potential and enhancing overall efficiency. Many people worry that robots will eventually replace humans in the workplace. However, this has not always been the case, as manufacturing floors still require human people to supervise the use of robots.

Robots liberate worker resources, which may then improve one's capabilities in areas of employment that need more physical effort. In addition, the requirement for people to oversee these robots might create more work opportunities.

5. Increasing Maximum Output Capacity

Because they eliminate human mistakes and stress, robots do more exact work and of higher quality. It is possible to identify future problems using robots. Robots may help enhance that capacity by saving on utility costs, generating cleaner workspaces, and reaching their ROI within two years. Since robots reduce expenses and free up labor resources, they can help local firms compete with foreign competitors. The emergence of robots in the industrial business is a positive development since it may enhance productivity, promote safety at manufacturing sites, and operate around the clock.

YONGU ELECTRONICS SUITED ALUMINIUM CASES

Now, the expansion of the robotics business owes a considerable amount of debt to the development of aluminum beginning in the middle of the 20th century and continuing onward. This debt was incurred since the development of aluminum paved the way for the growth of the robotics industry. Aluminum's strength, durability, lifetime, mobility, and flexibility have allowed the field of robotics to advance to where it is now. Without aluminum's properties, robotics would not be where it is today.

Aluminum is a material that is used in a wide range of components for robotic systems and is also a vital component in the process of producing automated systems. Aluminum helps provide solutions in circumstances where other materials cannot do so. This applies to scenarios involving small, machined components, large, automated machines, and even the robots used to make them.

YONGU's aluminum enclosures enable manufacturers and designers to get the most out of the goods and projects they are working on by maximizing their potential.

YONGU Eletrical Plastic Aluminum Enclosure K14C 90*35mm

Structure & Key Features

- Split type structure includes 1pc top housing, 1pc bottom housing, 1pc front panel, and rear panel.

- Good heat dissipation, easy to be assembled.

- L shape brackets for panels can be customized to wall mount.

- Dimensions, hole drilling, surface treatment, printing, etc., can be customized.

- Rugged and robust for heavy-duty use.

- Durable and can be used for a long time.

- Good quality aluminum material, al6063, and al5052.

- It can be used for din rail.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations: https://www.facebook.com/Foshan-Gof-Electronic-Machine-Co-Ltd-104706631749290

You can also contact us at +86 13326782625 or write us [email protected].