Your team devotes all their time and wisdom to your creative products. You can see that your product can already provide your customers with all kinds of application scenarios you can foresee. But this is not enough: she must be like Hepburn, like Monroe, and with a glance, she will leave an indelible impression. This is what you want. This is wh y you meet us. We meet many such visitors every day. When you decide to stay and talk with us, your product begins a new journey.

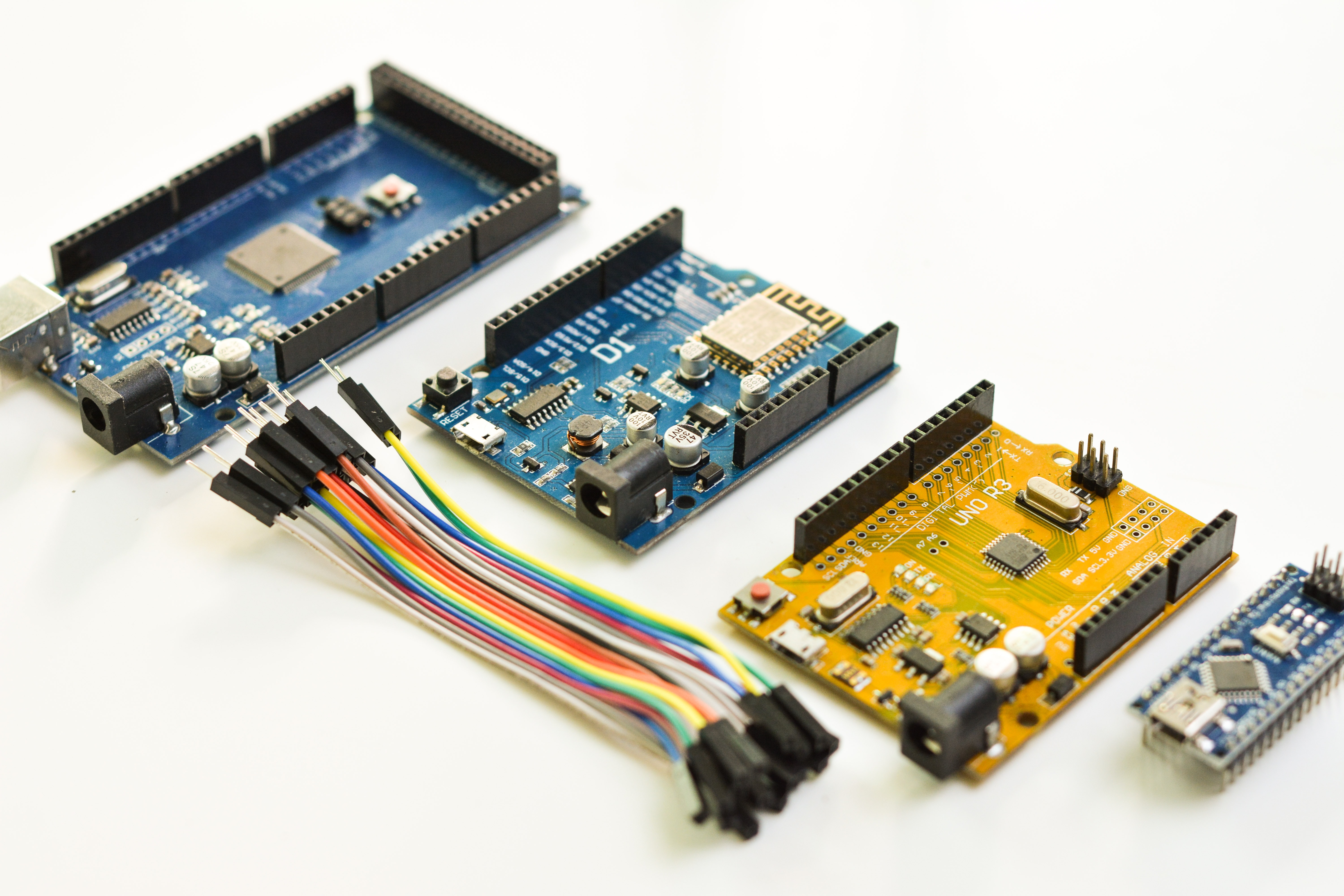

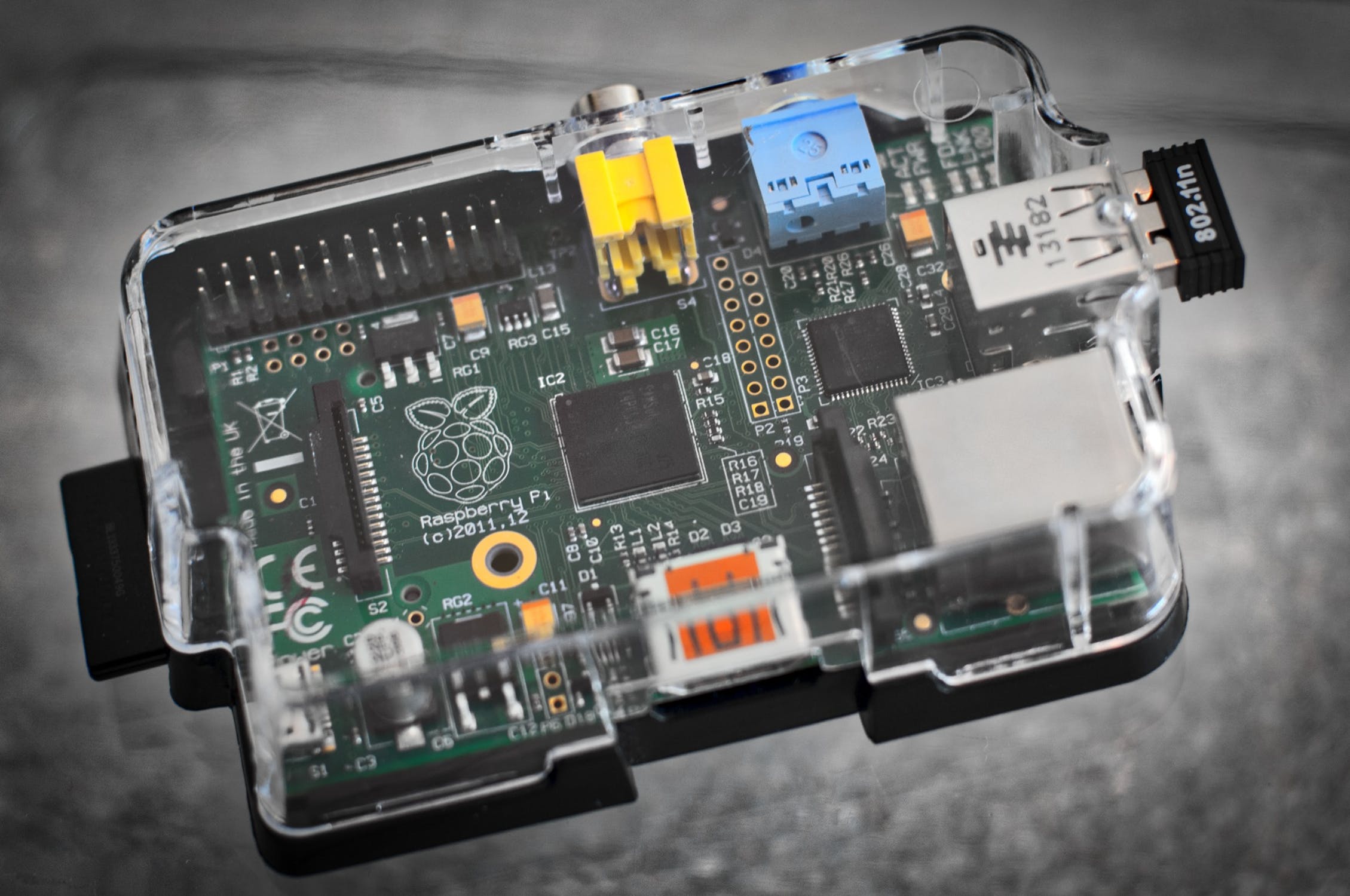

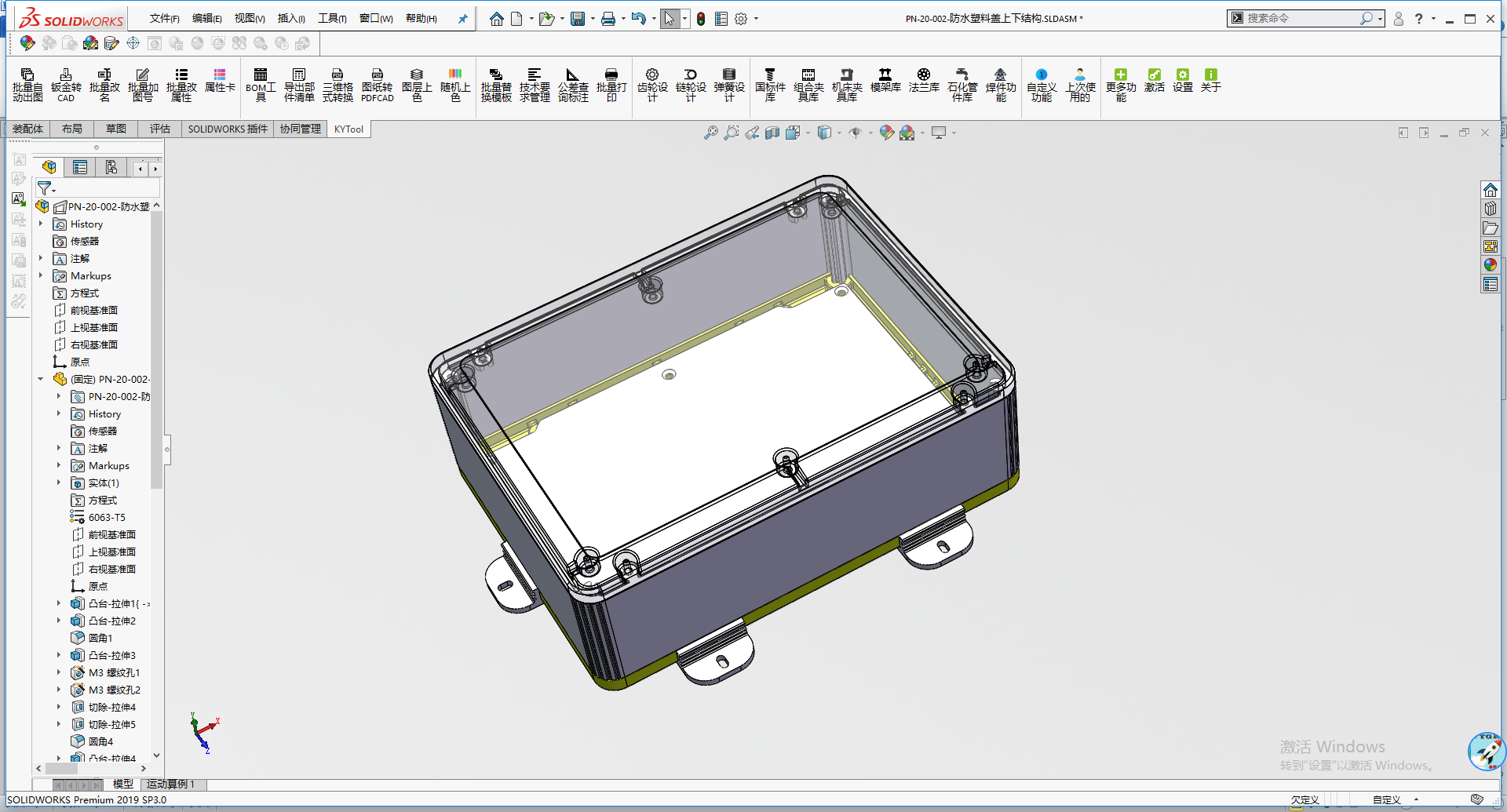

First of all, our customer service needs to know your expectations. If it is a blank for verifying the structure, we need to know what size is inside the product, and provide drawings,object. If it is a sketch, the key size must be marked. The key size includes the maximum length, width and height of the object, and the mounting hole. Location size. Finally, the most important thing is the relative position of different internal devices during installation. And most importantly, what holes drilling do you have on your product, such as various sockets such as power jacks? Button drilling holes, indicator drilling holes, display screen drilling holes etc., if any, must be explained to customer service. We strongly recommend that this information be recorded as a document for customer service. This is also convenient for you to check at any time. Our engineers can design according to this document. We are happy to accept model files and engineering drawings in various formats. Of course, the solidwork format and stp format are even better.

Of course, you want to see a finished product. Then you have to tell our customer service products what color you hope, what logo text to print, especially the prompt text and symbols on the panel. If you haven't made up your mind yet, no problem, our customer service will introduce our structural engineers and exterior designers to serve you. You can provide us with related pictures, vector format pictures, more suitable for product stickers.

Meanwhile, all you have to do is tell us clearly what is confirmed and uncertain. What is to be determined is variable, what is the variable range. Our exterior designers use sketching, modeling, and rendering to show what you think of the product without wasting any raw materials.

At the same time, our structural engineers will conduct structural modeling, process analysis, and material recommendations. In the appearance design, we begin to consider process optimization, strictly control the manufacturing cost, communicate with you in real time, and use reliable production technology to ensure product quality.

We firmly believe that your product is already very clear in your heart. All you have to do is to introduce her to us appropriately, and we present her concretely and truly. This is our job. We use PLM (Product Lifecycle Management, PLM) to perform full lifecycle management of your products. Adopt solidworks full process 3D design to provide you with 3D browsing model, what you see is what you get, you don’t have to worry about no engineering drawing experience, through 3D model you can put forward your design requirements, convenient and fast, deeply participate in product structural design, design As a service, service is design. Finally, you only need to confirm the design drawings that we have reached a consensus, and we can start production. All you have to do is wait for the shipping to deliver the product to you.

enclosure customized