In today's fast-paced industrial landscape, the demand for reliable and robust packaging solutions is paramount. Did you know that extruded aluminum boxes are becoming the go-to choice for many manufacturers due to their exceptional durability and strength? This article delves deeper into the advantages of using extruded aluminum boxes, particularly for custom aluminum enclosure solutions, and why they should be at the forefront of your material selection process.

The Benefits of Extruded Aluminum Boxes

Strength and Durability

The extrusion process enhances the structural integrity of aluminum, resulting in a product that is not only lightweight but also incredibly strong. This makes extruded aluminum boxes resistant to deformation under stress. The tensile strength of aluminum can reach up to 300 MPa, making it suitable for demanding applications where traditional materials may fail.

Corrosion Resistance

Unlike other materials, aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This property is especially beneficial in harsh environments where exposure to moisture, chemicals, or salt is common. For example, in marine applications, extruded aluminum boxes can withstand the corrosive effects of saltwater without degrading.

Customization Options

With advanced CNC machining capabilities, extruded aluminum boxes can be tailored to meet specific dimensions and designs. Whether you need unique shapes or sizes, customization is easily achievable. This flexibility allows manufacturers to create enclosures that fit their exact specifications, enhancing functionality and aesthetics.

Aesthetic Appeal

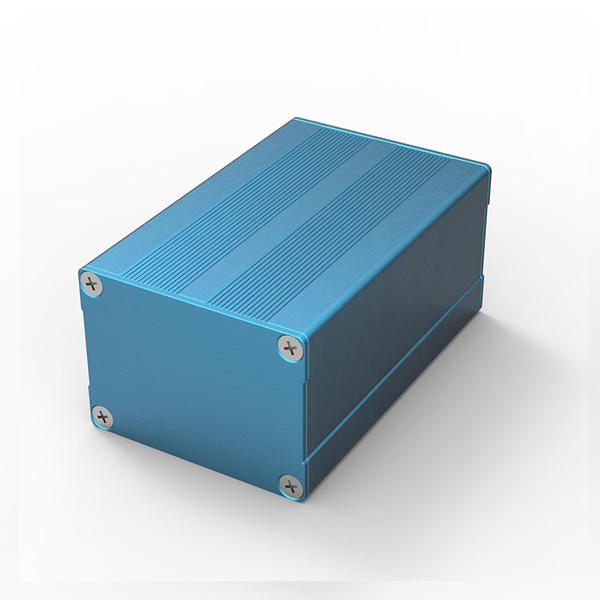

The sleek finish of extruded aluminum not only serves functional purposes but also enhances the visual appeal of products. Anodizing treatments can add color while further improving corrosion resistance. This means that businesses can align their product's appearance with their brand identity while ensuring durability.

Sustainability

Aluminum is a recyclable material, making extruded aluminum boxes an environmentally friendly option. Choosing sustainable materials can significantly enhance your brand's reputation. In fact, about 75% of all aluminum ever produced is still in use today due to its recyclability.

Applications of Extruded Aluminum Boxes

Electronics

Providing protection for sensitive electronic components is crucial in maintaining functionality and safety. Extruded aluminum boxes can shield devices from electromagnetic interference (EMI), ensuring optimal performance.

Automotive

In the automotive industry, weight reduction is critical for improving fuel efficiency without compromising safety. Extruded aluminum boxes are used in manufacturing parts that require lightweight yet durable enclosures, such as battery housings and control units.

Telecommunications

Housing equipment that must withstand outdoor conditions is vital for maintaining connectivity. Extruded aluminum boxes offer excellent protection against environmental factors like rain, dust, and extreme temperatures.

Medical Devices

Ensuring safety and durabilityin critical applications is non-negotiable in healthcare. Extruded aluminum enclosures are often used for medical devices due to their ability to provide a sterile environment while being easy to clean and maintain.

Why Choose YONGU for Your Extruded Aluminum Box Needs?

At YONGU, we specialize in manufacturing high-quality extruded aluminum boxes tailored to your specifications. Our commitment to excellence includes:

Customized Design Services: Our experienced design team collaborates with you to create 3D models and CAD documents that meet your precise requirements. This collaborative approach ensures that every detail aligns with your vision.

Advanced CNC Machining: With over ten CNC machines at our disposal, we ensure efficiency in both mass production and single sample creation without compromising on quality. Our precision machining capabilities allow us to achieve tight tolerances essential for high-performance applications.

Anodizing Treatments: We offer a variety of anodizing colors to enhance both aesthetics and performance, ensuring your products stand out while remaining highly functional. Anodizing not only improves corrosion resistance but also increases surface hardness, making it ideal for high-wear applications.

Quality Assurance: Each product undergoes rigorous testing to guarantee durability and performance under various conditions. Our quality control processes include material inspections and functional tests to ensure compliance with industry standards.

Conclusion

Choosing extruded aluminum boxes is not just about selecting a material; it's about investing in strength, durability, and versatility that can elevate your product offerings. By opting for YONGU's custom solutions, you ensure that your products meet industry standards while appealing to environmentally conscious consumers.

If you're looking to enhance your product offerings with reliable custom aluminum enclosure solutions, contact us today to discuss how our extruded aluminum boxes can meet your needs!