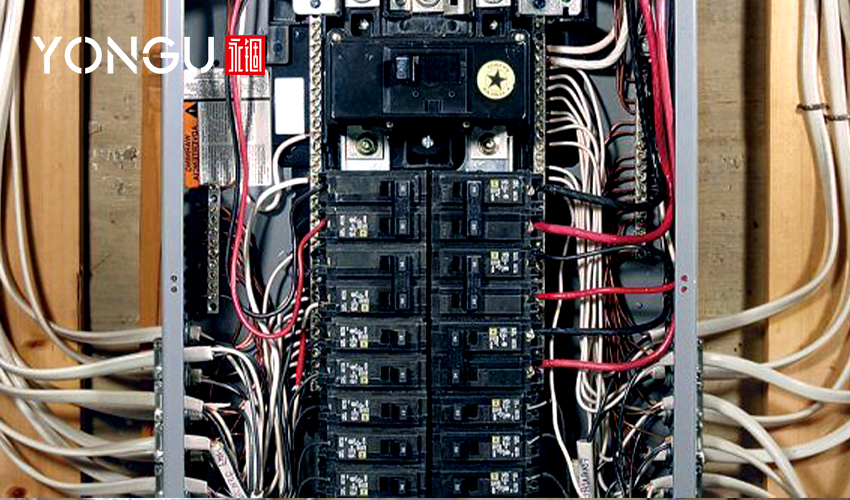

There is a main circuit breaker in the electric panel that regulates the electricity to the entire house. Additionally, you will see various breakers, each in charge of supplying energy to a different area of your house. The section of the house that each breaker regulates should be noted on the device's label.

Previously fuses were used in place of breakers. There were no electric panel switches if there was a fuse box. Instead, they will screw in fuses. You can have trouble getting insurance, or your premiums might increase. Fuse issues and home insurance are discussed lower.

The electricity of the house is supplied via an electrical metre outside, which then travels to the electric panel. You can use the main breaker in your electric panel to turn off this primary electricity supply. You may also find out the current of your electrical service from the main breaker.

Types of Electric Panel

Main Breaker

The main breaker panel manages the energy that flows into the house's various rooms. The power to your home, including the circuit breaker, can be turned off. They are categorised according to the amperage and the number of circuits they can support.

Fuse Box

These are intended to avoid overloading the circuit. Small, electric panel-compatible fuses make up fuse boxes. In cases with excessive current flow, the fuse will break out.

Main Lug Panel

The line wires enter the lugs used in the main lug panels. They have a special connection at the metre, being the main breaker. The main lug panel, which serves as a sub-panel, can be connected to the breaker at the main panel.

Sub Panel

These are ideal for homes when you need several circuits in one location. For example, the central panel supplies electricity to the sub-panels through a circuit. Since they lack dedicated disconnects, you can change how the current is distributed throughout the house.

Transfer Switches

These are appropriate for circuits that make use of a backup power source. Through the panel, it converts generator power to electrical power to function. Transfer switches come in both manual and automatic varieties.Components of Electric Panels

Main Circuit Breaker

This is comparable to disconnecting the main electric panel that serves any building or office entrance. Most industrial uses for main circuit breakers range start from 120V and goes up to 480V.

Lightning Protector

The lightning protector shields the circuit boards from getting damaged from overvoltage from the interior side of the panel caused by lightning or thunderstorms, or utility power surges.

Transformers

Transformers can decrease the voltage to 24V when incoming power is 120V or drop the voltage to 120V for different components based on the incoming voltage.

Terminals

The numerous wires come from various sources and are distributed among the various electrical equipment with the aid of these blocks.

PLC- Programmable Logical Controller

In essence, the control panel is a CPU on its own. The control panel's brain this component provides monitoring and management of all mechanical activities. There will be a variety of inputs and outputs to and from the production equipment's automated activities.

Contactors and Relays

These on and off switches operate mechanical processes by PLC instructions. More miniature relays are used to regulate appliances like fans and lighting. Larger relays referred to as contacts, manage more complex operations like motors.

Network Transister

This component serves as a communication means of a control panel, improving the connectivity that a PLC and the network-compatible machines have on the assembly line.

HMI- Human Machine Interface

These components enable the operator to monitor or control particular machine processes. For instance, common HMIs include video monitors, joysticks, buttons, switches, and keyboards.

Maintaining an Electric Panel

Another essential factor for electrical control panels is maintenance. A crucial component of designing a custom electrical control panel is making maintenance easier. Included in maintenance efforts should be:

- Components, wiring, and terminals with prominent labels

- Ability to keep track of the health of different electrical connections

- Control of dust and particles inside the enclosure

- Measures to manage pests

Electric Panels at YONGU

YONGU electric panel enclosures are a perfect choice for industrial and commercial applications since they are waterproof. Our enclosure boxes meet and often surpass various IP standards and are specifically made to protect electric control panels from severe conditions. In addition, any outdoor electrical application may easily find the ideal solution thanks to the wide range of sizes, designs, and materials available. In addition, outdoor electrical boxes are appropriate for various industries, including automation, alternative energy, telecommunications, and more.YONGU Eletrical Plastic Cover Box K21C 160*55mm

This enclosure can be greatly used for electric panels commercially and resedencially. Its width is about 160 mm, its height is 55 mm, and its length can be customized.It has carbon steel nickel plated cross countersunk head skewers to make it robust and durable. It had plastic protect covers and aluminum case to secure form electric shocks and to achieve conductivity is contract between rough inner surface.

Conclusion

Due to the variety of residential and commercial enclosures we offer, Yongu Box is an industry leader in delivering enclosures with affordable protection. Each of these enclosures has something special to offer and can be the perfect option for your industrial enclosure needs. Additional factors specific to each device and industry will also influence your choice.For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].