Why is It Important to Know Which is Better, Custom or Modified Enclosure?

A modified enclosure will typically be manufactured more quickly and at a lower cost than a custom enclosure. It takes time to create detailed designs, alter or purchase tooling, and meet certification requirements for custom enclosures. Modified enclosure IP rated is simpler if the original enclosure was correctly rated. It can take up to six months to begin from scratch and obtain an IP rating.Remember that quantity might also have a significant impact on your choice. For example, it will not be cost-effective to produce 100 or even 1000 units if tooling costs. On the other hand, if you are making 100,000 pieces, it would probably be beneficial to have a team that is quickly assembled and maintained and closely reflects your company's brand.

Advantages of Modified Enclosures

It could seem simple enough to choose the basic enclosure that fits your demands the best and customise it to accommodate your electrical equipment, given the variety of alternatives available. Although this choice might be practical and initially more affordable, there are many factors to consider.Here are some of the main advantages of having modified enclosures.

Numerous Configurations

Modified enclosure systems have pre-made holes that are positioned at predetermined measurement distances. It implies that you can modify a frame without drilling or welding by simply adding your most typical accessories inside. You can make an endless number of combinations by joining several modified structures.

Modularity in Building

Long-term advantages come from having the flexibility to organise your box and its components as necessary. For example, an assembly can be as simple or sophisticated as the user, designer, and integrator see fit using a modular system. A modular enclosure structure will also be able to accommodate multiple door options for simpler access.

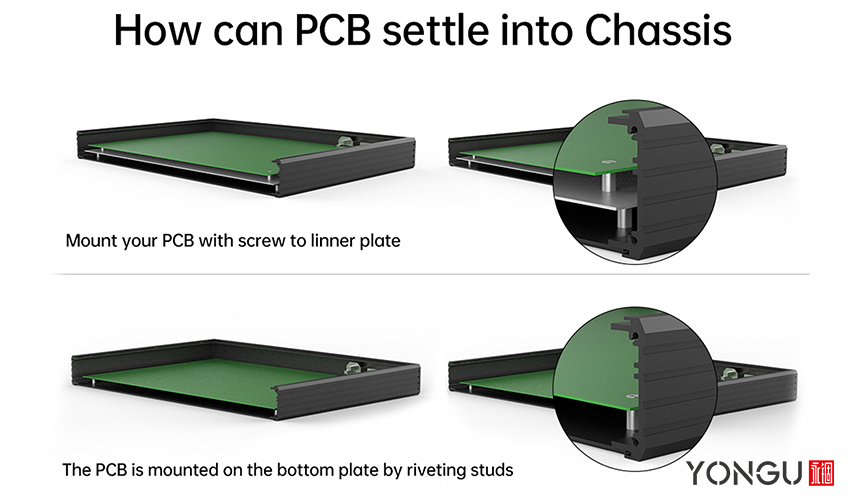

Faster and safer installation and mounting

You can use the modular enclosure's front, side, or rear to move panels into and out. It is made feasible by the use of rails. Compared to the unibody method, which involves lying the enclosure on its back and removing the panel with a crane or forklift, this saves time and improves safety. Additionally, a modular enclosure's design enables a wider opening and, consequently, a larger mounting panel for simpler attachment. Finally, installing electronics into a modular frame is quicker, saving you both time and money.

Advantages of Custom Enclosures

Prototyping

As part of the custom enclosure design process, we produce working prototypes for our clients so they may run their tests. Before going into production, You might request design changes after the prototype has been examined and tested.

Design Engineering

You can redesign your enclosure with the aid of a design engineering team. You won't have to spend as much time coming up with ideas because you'll get their professional opinion.

Design Alternatives

You'll have many choices regarding powder coat paint colours and design elements. By customising, you can choose the design and colour you desire rather than being forced to settle for a predetermined option.

Methods to Manufacture Custom Enclosure

3D printing

Create a 3D model of your completed design and a prototype unit, and test it. Make the necessary modifications with little expense based on the outcome of your trial. Move forward with small-scale manufacturing runs when the final design has been approved.

Tool-less Manufacturing

Consider employing toolless manufacturing for modest production runs, depending on the demand for the product and your level of confidence in it. However, before switching to a more long-term supply alternative, this approach enables clients to monitor sales and ensure the product operates well in its container.

Using Injection Moulds

Spending work on the enclosure's refinement in early phases will give you the confidence to order a tool in bulk and take advantage of the cost advantages that custom injection moulding provides over toolless alternatives.

Why YONGU is Best for Custom Enclosures

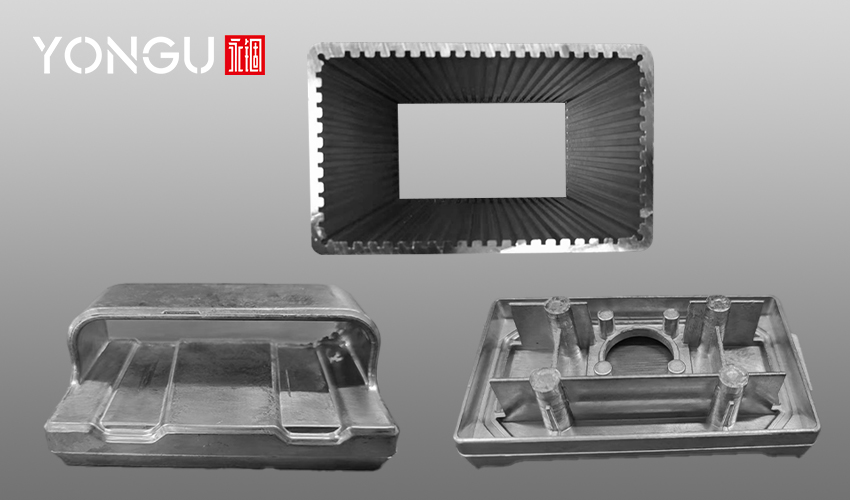

Yongu services are committed to providing an excellent customer experience. You can rely on us to produce your customised enclosure on time and within your requirements. Yongu Box is your best option if you want a full-service supplier of electrical enclosures.Our CNC machines provide the highest flexibility and cutout accuracy, guaranteeing your components will fit as intended. High-definition images printed directly onto enclosures do not peel, bubble, or scratch. Your ordinary box may become a high-end finished good with precision cutting and superior graphics from Yongu Box. Our quality and customer service are unequalled due to our quick lead times, lack of minimum order requirements, and years of experience in the electronics/electrical sector.

Conclusion

If you like one of our enclosures, but it does not meet your needs, we may change the design to create the ideal custom solution. In addition, we collaborate with our clients to create new, specialised solutions. View an example of one of our original solutions, go through all of our engineering and electrical enclosure design services, or contact us for additional information.We provide quick and simple customisation options for making unique cutouts and printing on many of our enclosure models. For further information and customised product of your requirements.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].