Instrument enclosures play a crucial role in safeguarding delicate equipment, ensuring their optimal functionality, and protecting them from environmental factors. These enclosures come in various types, customizable options, and specialized forms tailored for specific industries or applications. In this post, the author would give a full introduction to the instrument enclosures.

What is an Instrument Enclosure?

An instrument enclosure refers to a protective housing designed to shield sensitive electronic instruments, devices, or equipment from external elements and potential hazards. It serves as a physical barrier, safeguarding these instruments from dust, moisture, electromagnetic interference, extreme temperatures, and other environmental factors that could compromise their functionality or longevity.

Can Instrument Enclosures be Customized?

Instrument enclosures often offer customization options to meet specific needs. These customization can vary widely, allowing for adaptations in size, shape, material, color, mounting options, additional cutouts for connectors or displays, and more.

Customization might involve altering the dimensions of the enclosure to accommodate specific instruments or equipment, adding specialized features such as cooling systems or cable management solutions, or even integrating branding elements for corporate identity purposes.

Manufacturers of instrument enclosures usually offer customization services to ensure that the enclosure fits the precise requirements of the instruments it will house and the environment in which it will operate. This flexibility enables industries to optimize the functionality and protection of their sensitive equipment by tailoring the enclosure to their unique needs.

If you want to get the customized enclosure, you can contact YONGU to get the best customized instrument enclosures.

Customization might involve altering the dimensions of the enclosure to accommodate specific instruments or equipment, adding specialized features such as cooling systems or cable management solutions, or even integrating branding elements for corporate identity purposes.

Manufacturers of instrument enclosures usually offer customization services to ensure that the enclosure fits the precise requirements of the instruments it will house and the environment in which it will operate. This flexibility enables industries to optimize the functionality and protection of their sensitive equipment by tailoring the enclosure to their unique needs.

If you want to get the customized enclosure, you can contact YONGU to get the best customized instrument enclosures.

What are the Different Types of Instrument Enclosures Available?

Instrument enclosures come in various types, each designed to suit different environmental conditions, applications, and types of instruments they protect. Here are some common types:

●Plastic Enclosures

These are typically made from materials like ABS (Acrylonitrile Butadiene Styrene), polycarbonate, or fiberglass. They're lightweight, cost-effective, and suitable for indoor use or environments not exposed to extreme conditions.

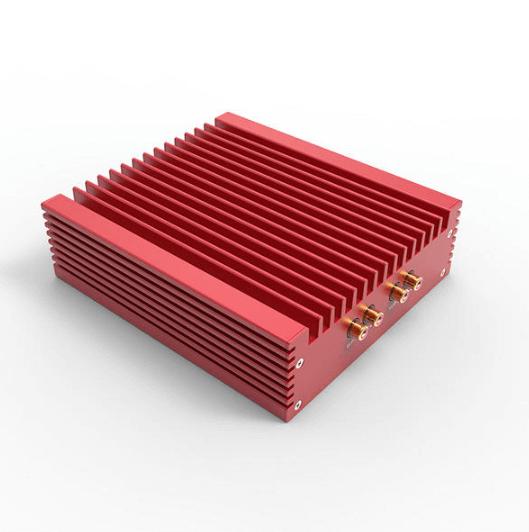

●Metal Enclosures

Constructed from aluminum, steel, or stainless steel, metal enclosures offer sturdier protection. They are ideal for outdoor use or harsh industrial environments due to their durability and ability to shield against electromagnetic interference.

●Weatherproof Enclosures

Specifically designed to withstand harsh weather conditions, these enclosures are often waterproof and resistant to extreme temperatures. They're suitable for outdoor installations where protection from elements is crucial.

●Rack-Mount Enclosures

Commonly used in data centers and networking setups, these enclosures are standardized to fit into racks, allowing for easy installation and management of electronic equipment.

●Explosion-Proof Enclosures

These enclosures are designed to prevent internal explosions from causing external hazards. They're commonly used in industries where explosive gases or materials are present.

●Instrument Cases

Often used for portable instruments, these cases provide protection during transport and usage. They can be made of various materials like plastic, metal, or specialized composite materials.

●Handheld Enclosures

Designed for instruments meant to be operated while held, these enclosures are ergonomically designed for ease of use while providing necessary protection.

The choice of enclosure type depends on the specific needs of the instruments, the operating environment, and the level of protection required. Each type offers distinct advantages in terms of durability, protection, and suitability for different applications.

The choice of enclosure type depends on the specific needs of the instruments, the operating environment, and the level of protection required. Each type offers distinct advantages in terms of durability, protection, and suitability for different applications.

Conclusion

In conclusion, understanding the diverse types, customization options, and specialized variants of instrument enclosures is vital when selecting the appropriate housing for sensitive equipment. By choosing the right enclosure, industries can ensure the optimal performance and longevity of their instruments in various operating environments.